A brass shavings briquetting press machine is a specialized piece of equipment used to compress and ...

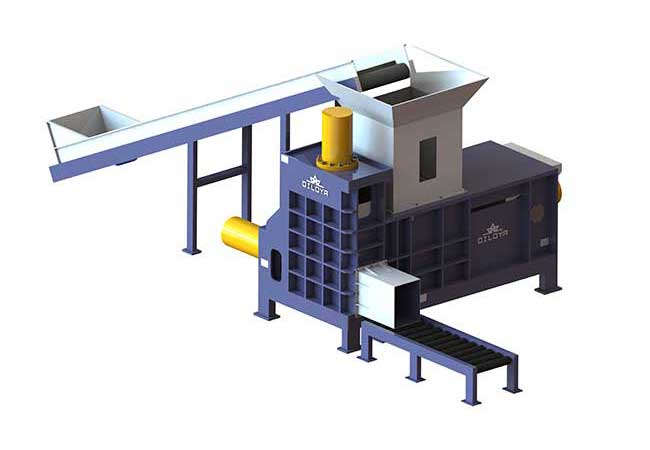

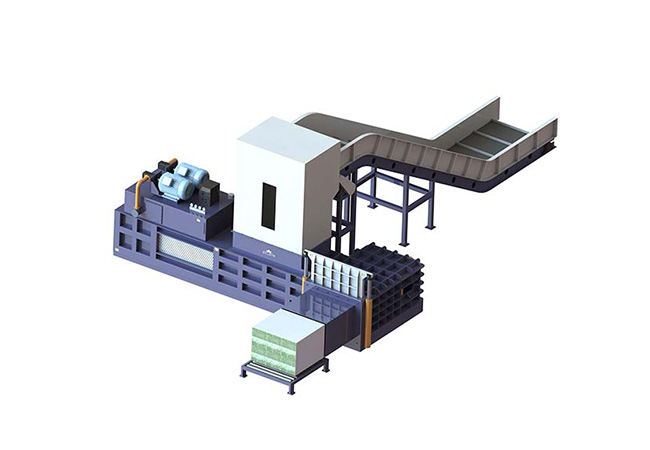

Maize Cob Bagging Compactor Machine mainly used in agriculture industry, it is composed of three sections: hydraulic system, electrical system, main frame, can handle all kinds of silage such as silage, hay straw, wheat straw, haylage, Alfalfa, chopped straw, corn silage, etc...

Working Principle: The corn cob is put into the baler hopper by conveyor, then the side cylinder will press the silage to the limit several times which is set in our factory, then use a woven bag or plastic bags to hold the bale when the main cylinder pushing the bale out automatically, this way, the bale is finished completely, then start the next bale continuously.

We not only produce above machines, we also have other hydraulic baler machine, hydraulic shear machine, metal/plastic scrap shredder machine and plastic scrap granulator/crusher machine such as Corn Cob Baler Machine With High Quality, Marine Baling Press, Baler Machine Clothing, Clothes Vertical Baler, Copper wire granulator, Hello Baler,Big hdpe pipe shredder, waxed occ shredding machine, a video of shredder shredding cardboard and hearing aids, Baling Used Clothes In Canada, Sk baler, New Baler For Used Newspaper, Price For Indian Scrap Baling Machine, How To Make Cotton Bales Packing Cloth, Xt baler, Press Machine For cotton Seed, Rag clothes recycling, Tcm Baler Waste Paper Cartons Press, Jewel baler, Pres Horizontal Waste Paper, Aluminum Chips Briquetting, Scrap taxi baling shear, Jiajiang baler, Silage baler machine, Bailing Of Fibre In Sisal, Cartoon Waste Cartoon Pressing Machine, Csj baler, Light Steel Baler, Plastic lumps shredding machines wow, Tag rag packing machine, Sinobaler, Clothes Bale Press, hydraulic clothing baler machine, Square bale maize press hydraulic press for silage, Nick baler, Fully Automatic Steel Baling Press Machine 250 Ton, Excavator Hydraulic Shears, Wipe rags packaging machine, Nkbaler, Wheat straw baler, Rice Husks Compress Baler, Newspaper Compress Baler For Sale, Enepat baler, Peanut Shell Recycling, New Good Quality Peanut Shell Baler, Used Clothing Baling Machine, Gradeall baler, Baler Enerpat, Tcm Baler- Horizontal Waste Paper Baling, Baler Cardboard Compactor For Sale, Valan wiper baler, Copper wire shredding system, Bale Press Short Fiber, Cotton rags manual bale press, Aupu machinery baler, Chip Briquetting Machine Waste Iron Chip Briquette Machine, Trash shredder with metal separator, Wood waste press, Coveyor belt paper bailer, Making briquettes from wood chips, Corn cob briquettes, Wiper Compress Baling Machine, Machine Baler Double Feeder Wiping Rags 45Kg etc… And we can make the machine according to your special requirements, please feel free to contact with us if you have any requirements.

Parameter

Model | Bale Size (mm) | Bale Weight (Kg) | Power (Kw) |

HBD100 | 500X300X200 | 10-20 | 18.5 |

HBD150 | 600X300X300 | 15-30 | 22 |

HBD200 | 700X400X300 | 25-45 | 30 |

HBD250 | 750X430X310 | 35-50 | 37 |

HBD300 | 750X430X310 | 40-60 | 45 |

HBD400 | 750X430X310 | 50-80 | 30X2 |

If you have any special requirements, we will customize according to your special needs.

Advantage

1. Adopts horizontal continuously push out type with Semi-auto bagging system.

2. Adopts latest design of three ram, bale density is more higher than two rams, more economical.

3. Fully automatic control, high efficiency, save labor cost, transportation cost, stock cost and space.

4. Bale size and bale weight can be customized according to your special requirement.

5. Output capacity varies from 2 to 5tons per hour, more options for your choices.

6. Bale weight can be up to 20-50kg per bale, and output bale quantity can be up to 100-120 bales per hour, more efficient.

7. Auto-inspecting system for silage to start or stop the machine automatically, save power energy, easy to operate and maintain.

8. Adopts German Hydraulic technology to promise the machine run smoothly, durable and reliable.

9. Adopts international brand of hydraulic pump and valves to prolong the service life of the baler machine.

Application

The baler machine can press below materials:

FAQ

1. How to choose the suitable right Automatic Corn Cob Baler? First, you need to confirm what bale size and bale weight will you need after pressing? As for this issue, you can make a investigation in your market and found out what bale size and bale weight are popular, then you can know the bale size and bale weight you need, and you can easily choose suitable Maize Cob Bagging Compactor Machine;Then, make a investigation that how many of these wiping rags will be needed, this way, you can confirm how many bales you need to press per day or per month, this is very important for choosing the right Corncob Bagging Press Machine;Last, after confirming these issues, we can suggest you suitable Maize Cob Pressing Baler and best offer accordingly. 2. What bale weight and bale size can Cob Packer Machine can produce? The Corncob Packing Machinery can produce 20kg, 25kg,30kg,35kg, 40kg, 50kg, 60kg, 100kg bale, and this is our normal bale size, we an also customize the baler machine according to your special requirement, if you want other bale size such as 50lbs, 60lb,80lb, 100lb, 150lb, 200lb bale weight, and other bale weight. 3. Are you a manufacturer or a trader of Corncob Bagging Press Baler? We are true manufacturer of producing Maize Cob Pressing Baler Machine, we have our own factory, our own design and developing team, and we have many years' experiences in producing the hydraulic baling machine. 4. What is warranty period time of the Horizontal Crushed Corn Cob Baler? The warranty time of the Corncob Bale Baler Machine is 12 months, this is our normal warranty time, if you want to prolong the warranty time, we can charge you lower cost than other suppliers such as enerpat baler, sk baler, nick baler, sinobaler, xt baler, jewel baler etc...And within the warranty time, we are responsible for Corn Compactor Machine in case of any problem except misoperation by people. 5. Are you responsible for installation of the Maize Cob Baler Machine? Yes, of couse, we are responsible for the Corncob Baling Machine, and this kind of baler machine is very easy to install, just need to connect to the power supply, and then start to test the machine is ok, because hydraulic system and electrical are all setled when shipping.We also can send our engineer to your place to help you install the Corn Cob Bagging Baler, and you need to pay some fees for air tickets and salary for the engineer. 6. What is payment term of the Corn Cob Grinding Packing Machine China Manufacture? The payment term of the Best Sell Hydraulic Corn Cob Baling Machine are T/T, L/C, and it is flexible depend on special case, because some countries just accept L/C, and some countries accept other payment terms. 7. Do you have CE certificate or other certificate of the Corn Core Compress Machine? Yes, we have CE certificate of the Corn Cob Baler Machine Made In Henan, we also have other cetificates such as SGS, IOS, TUV, also have many patents of the baler machine. 8. Which countries have you exported the Corncob Compressing Baler Machine? We have exporged the Compress Corncob Packing Machine to 100 more countries such as Japan, Thailand, Malaysia, Singapore, Indonesia, India, Pakistan, Sri Lanka, Iraq, Iran , Qatar, Kuwait, Oman, Turkey, Finland, Sweden, Norway, Iceland, Denmark, Russia, Poland, Czech, Germany, Austria, Britain, Ireland, Netherlands, Belgium, France, Greece, Romania, Bulgaria, Albania, Slovenia, Croatia, Italy, Spain, Portugal, Egypt, Chile, Argentina, Ecuador, Canada, America, USA, Australia, New Zealand, South Africa, Mexico and other countries. 9. Do you have a agent or distributor of the Corncob Compacting Wrapping Machine in our country? We don't have agent or distributor of the Corn Cob Press Baler, we directly export the baler machine to you, because this way, we can leave more profit space to you, and this is also the reason why our baler price is more competitive than other supplier such as Nick baler, Xt baler, Sinobaler, Csj baler, Jewel baler, Sk baler, and the other reson that we are true manufacturer, we have our own factory, technical team.

Hotline : +86 152 2134 7650

Hotline : +86 152 2134 7650 Email : info@diloya.com

Email : info@diloya.com

Product

Product Phone: +86 152 2134 7650

Phone: +86 152 2134 7650 E-mail: info@diloya.com

E-mail: info@diloya.com Address: YinShang Industrial Zone, JiaDing District, Shanghai City, China

Address: YinShang Industrial Zone, JiaDing District, Shanghai City, China