Scraping a compressor for recycling metals is a valuable and environmentally responsible practice. C...

| Basic Infomation | |

Status Of Machine: Totally New; | Pump Brand: JiangSu Hengyuan; |

| Additional Information | |

Lead Time: 15 Days; | None-Load Cycle: 12-15s; |

| Package And Delivery | |

Package: Wood package, Plastic Films, Nude Packing | Delivery: Ocean Shipping |

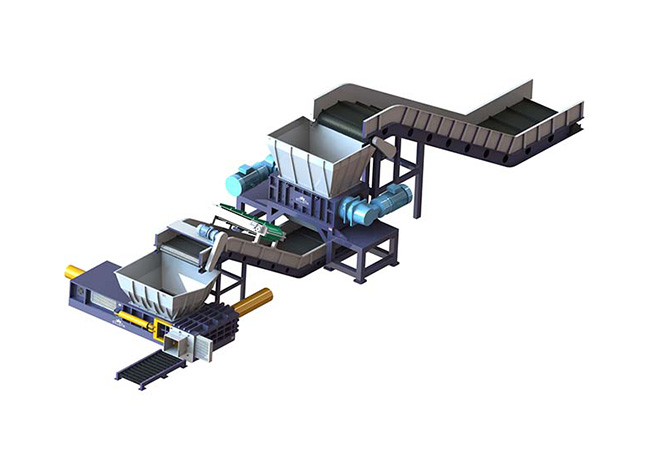

The Copper Cloves briquetting machine is mainly compress the metal chips, aluminum chips, brass chips, bronze shavings, aluminum shavings into small bales with high density for metal manufacturer to remlelt again, easy to transport, stock and can highly improve the rate of melting, can make more profits, it has other names such as Aluminium Shavings Briquette Press,Metal Chip Baling Machine,Bronze Powder baler,Brass Chips Briquetting Machine,Brass Swarfs briquetting press,Waste Scrap Cast Iron Briquetting Press,Aluminum Metal Chip Briquetting Machine,Waste Aluminum Copper Scrap Briquette Recycling Machine,Iron Chips Briquetting Press Machine.

A Waste Metal Chip Briquetting Press is a type of machinery used to compress metal chips or swarf (small fragments and fine particles of metal produced during machining operations) into dense briquettes.

This process offers several benefits, including:

1. Volume Reduction: Compressing the metal chips reduces their volume significantly, making storage and transportation more efficient.

2. Value Addition: By removing coolant and oil from the chips, the resulting briquettes have a higher metal content, which can be sold at a better price.

3. Environmental Benefits: The process helps in reducing pollution as it minimizes the risk of coolant and oil leaking into the environment.

Key components and features of a typical Waste Metal Chip Briquetting Press include:

- Hydraulic System: Provides the necessary force to compress the metal chips.

- Coolant Separation Mechanism: Ensures that the oil and coolant are removed from the chips before compression.

- Briquette Mold: Shapes the compressed metal into a desired form, often cylindrical or rectangular.

- Control Panel: Allows for adjusting settings such as pressure and cooling time.

- Safety Features: Such as emergency stop buttons and protective guards to ensure safe operation.

These machines are commonly used in automotive, aerospace, and general manufacturing industries where large amounts of metal chips are generated during machining processes.

Parameter

Model | Bale Size (mm) | Bale Weight (Kg) | Power (Kw) |

BP150 | Φ70X(40-60) | 1-1.8 | 15 |

BP200 | Φ80X(40-70) | 1.2-2.8 | 18.5 |

BP360 | Φ120X(60-100) | 4.8-6.5 | 30 |

BP400 | Φ130X(70-100) | 6.2-8.1 | 37 |

BP500 | Φ140X(80-120) | 7.6-9.4 | 2x22 |

BP630 | Φ160X(90-120) | 8.5-10.5 | 2x30 |

If you have any special requirements, we will customize according to your special needs.

Product Show

|  |

|  |

|  |

|  |

Advantage

> Enough spare parts with lower cost to keep the machine non-stop.

> One Button automatic PLC Control, just need to push one button, you can operate the machine continuously.

> Adopts Vertical simple structure, easy to operate and maintain.

> Strong structure of the machine, reliable, stable and durable, let you make more money.

> Schneider electrical components prolong the service life of the machine.

> Latest design of the machine to let you use the best the machine all the time.

> The bale weight ranges from 1.5kg to 22kg, more options for your choices.

> Output capacity can be up to 200-300bales per hour, more efficient.

Application

The baler machine can press below materials:

|  |  |  |

| Copper Rice Granules | Bronze Chips | Brass Chips | Copper Shavings |

|  |  | |

| Iron Cast Chips | Aluminu Shavings | Metal Chips | Stainless Steel Chips |

|  |  |  |

|  |  |  |

FAQ

> Do you provide video support of Bronze Shavings block making machine?

Yes, of course, we are providing the video support which includes installing the baler machine, testing and operating the machine, we also can guide you to replace parts and maintenance via video call.

> Do you have a agent of Iron Metal Briquetting Press in our country?

No, we don't have agent or representative in your country, we directly export the machine to our end users, this way, the price will be lower, and end users can get more money.

> What is payment term of Hydraulic Briquette Pressing Of Metal Chips?

The payment of the briquetting press machine is 30% TT as deposit, and 70%TT balance paid 7 days before shipment, and LC is also acceptable, it is flexible depends on amount of the machine.

> How can i know you are a manufacturer or trader of Aluminum Metal Chip Briquetting Machine?

You can visit our factory personally, also you can ask technical drawings such as 2D drawings 3D Drawings, we have professional technical team working on this, and will not give you these if a trader, because they don't have ability on this.

> Are you a manufacturer or a trader of Iron Chips Briquetting Machine?

We are true manufacturer of briquetting press machine, we have our own technical team, R&D team, have many processing machines, and you are warmly welcome to visit our factory personally.

> What are the service requirements of the High Quality Metal Chips Briquette Press?

No need special requirements, just contact with our technical team, that is ok, we can get everything done.

> Which country have you exported the Aluminium Briquetting Machine?

We have exported the bbriquetting press machine to many countries such as Japan, Thailand, Malaysia, Singapore, Indonesia, India, Pakistan, Sri Lanka, Iraq, Iran , Qatar, Kuwait, Oman, Turkey, Finland, Sweden, Norway, Iceland, Denmark, Russia, Poland, Czech, Germany, Austria, Britain, Ireland, Netherlands, Belgium, France, Greece, Romania, Bulgaria, Albania, Slovenia, Croatia, Italy, Spain, Portugal, Egypt, Chile, Argentina, Ecuador, Canada, America, USA, Australia, New Zealand, South Africa, Mexico and other countries.

Hotline : +86 152 2134 7650

Hotline : +86 152 2134 7650 Email : info@diloya.com

Email : info@diloya.com

Product

Product Phone: +86 152 2134 7650

Phone: +86 152 2134 7650 E-mail: info@diloya.com

E-mail: info@diloya.com Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China

Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China