VLB Series Vertical Lifting Chamber Baling Press Machine, mainly compress short fibers, waste yarns,...

| Basic Infomation | |

HS Code: 8462919000 Payment Term: T/T L/C Output Capacity: 8-10bales/Hour Quality Control: ISO9001, 2008 Brand: Diloya Test Video Before Shipment: Provide Bale Weight: 40-1000kg Chamber Type: Lifting Type Transportion: Ocean Shipping Applicable Material: Old Clothes | Hydraulic Power: 300-1500kn Color: Ral5013 or Per your requirement Status Of Machine: Totally New Model Series: VLB Series Packaging: Nude Packing/Wooden Package Core Components: Pump, Motor Type: Vertical Type Motor: China Famous Brand Trade Term: FOB CIF CNF Video Support: Yes |

| Additional Information | |

Steel Plate: Q235B Delivery Time: 30 Days Electrical Components: Schneider Productivity: 30-50sets/Month | Min. Order: 1 Set Working Pressure: 15Mpa Certificate: CE TUV ISO Place of Origin: China |

| Package And Delivery | |

Package: Wood package, Plastic Films, Nude Packing | Delivery: Ocean Shipping |

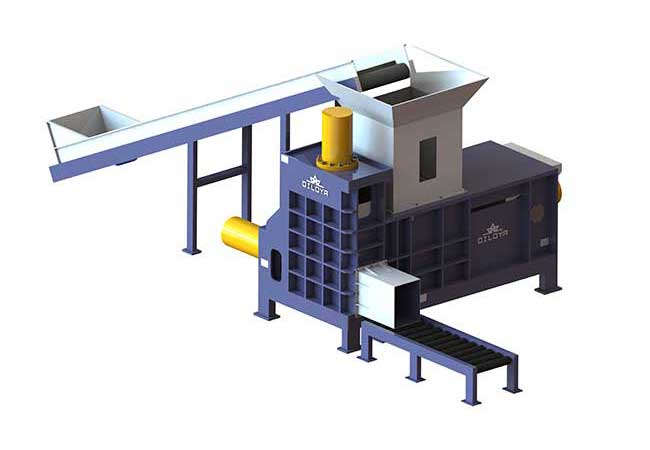

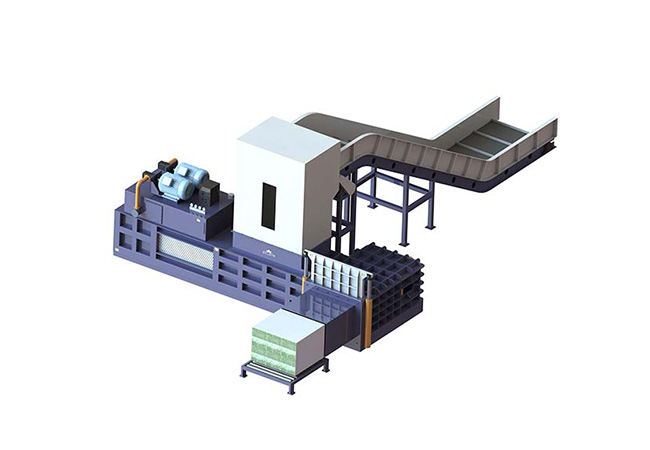

VLB Series Vertical Lifting Chamber Baling Press Machine, mainly compress short fibers, waste yarns, waste clothes, scrap clothing, cotton, wools, rag wipers, wiping rags, old clothes etc..

VLB Series Vertical Lifting Chamber Baling Press Machine mainly used in wool and wiping rags industry and many waste disposal recycling center, it is composed of three sections: hydraulic system, electrical system, main frame, can handle all kinds of old clothes, rag wipers, wiping rags, cotton rags, short fibers, yarns, cotton, wools, etc...

Working Principle: The waste clothes is put into the box chamber by people or conveyor, then the main cylinder will press the old clothes to the limit several times which is set in our factory, and then bundle the bale manually by hand, and the bale will be turned out when the main cylinder lifting up, this way, the bale is finished completely, then start the next bale continuously.

A 50kg baling machine for old clothes is a piece of equipment used to compress and bundle used textiles, such as clothing, into compact bales that weigh around 50 kilograms (about 110 pounds). These machines help in reducing the volume of textile waste, making it easier and more cost-effective to transport and store.

Key features and considerations for a 50kg old clothes baler:

1. Capacity: The machine should be capable of producing bales weighing approximately 50kg.

2. Baler type: There are different types of balers available, including vertical balers and horizontal balers. Vertical balers are generally smaller and more suitable for smaller-scale operations, while horizontal balers can handle larger volumes and are better for industrial use.

3. Material handling: Consider how the machine will accept input material. Some models may require manual loading, while others might have conveyor systems or automated feeding mechanisms.

4. Power source: Determine whether the machine operates on electricity, hydraulic power, or another energy source.

5. Production rate: Consider how many bales per hour the machine can produce, which will depend on factors like bale size, material density, and machine efficiency.

6. Maintenance requirements: Look for a machine with easy access to components for maintenance and repair.

7. Safety features: Ensure the machine has appropriate safety features, such as emergency stop buttons, safety guards, and proper operating instructions.

8. Cost: Evaluate the initial purchase price, as well as ongoing operational costs like electricity usage and maintenance.

9. Compliance: Make sure the machine meets relevant safety and environmental regulations.

10. Space requirements: Consider the dimensions of the machine and the space needed for operation and storage.

When selecting a 50kg old clothes baler, consider your specific needs and the scale of your operation. If you're dealing with a small volume of materials, a smaller vertical baler might suffice. For larger-scale operations, a more robust horizontal baler would likely be necessary.

Parameter

Model | Bale Size (mm) | Bale Weight (Kg) | Power (Kw) |

VLB30 | 700X400X(300-600) | 40-90 | 5.5 |

VLB40 | 760X520X(500-900) | 80-130 | 7.5 |

VLB60 | 1100X700X(500-900) | 150-250 | 11 |

VLB80 | 1200X800X(600-1000) | 200-350 | 15 |

VLB100 | 1200X800X(600-1000) | 300-400 | 22 |

VLB120 | 1100X1100X(600-1000) | 400-600 | 30 |

VLB150 | 1350X750X(600-1200) | 500-700 | 22X2 |

If you have any special requirements, we will customize according to your special needs.

Product Show

|  |

|  |

|  |

|  |

|  |

|  |

Advantage

1. Adopts lifting chamber with vertical structure, easy to operate and maintain.

2. Bundle the bale manually by human, suitable for small recycling center of rag wiper and others.

3. Manual and electrical button control, two options for your choices.

4. Bale length and bale weight can be adjustable according to your special requirement.

5. Output capacity varies from 300 to 1500kg per hour, more options for your choices.

6. Adopts German Hydraulic technology to promise the machine run smoothly and stable.

7. Adopts international famous brand of hydraulic pump and valves to prolong the lifespan of the baler machine.

8. Lower price, economical option for your business, it's ideal baler machine for your best choices.

Application

The baler machine can press below materials:

FAQ

> What is warranty time of the India Textile Press Machine?

The warranty time of the baler machine is 12 months normally, also can you can pay extra fees for more times such as 24 months or 36 months, within the warranty time, we are responsible for the baler machine except the spare parts.

> How to maintain Industrial Wipers Scrap Baler?

When you were operating the baler machine, you need to clean the oil tank every 3 months, and check the wire, and oil pipe leakage or not, and also check the bolt every shift, you can find all maintenance items in the user manual.

> Are you a manufacturer or a trader of Rag Wiper Bagging Machine?

We are true manufacturer of used clothes baler machine, we have our own technical team, R&D team, have many processing machines, and you are warmly welcome to visit our factory personally.

> Do you provide video support of Rags compacting machine?

Yes, of course, we are providing the video support which includes installing the baler machine, testing and operating the machine, we also can guide you to replace parts and maintenance via video call.

> What are all the skills required to operate a White Cotton Wiping Rags baler manufactured by Diloya?

No special skills, just read the user manual carefully before operating the machine, if you have any questions, feel free to contact with us, we can help you at any time.

> What profits can we get from the Clothes packing machine clothing vertical baler safety?

You need to know price of recycling old clothes, and price of the bales you sell to your end users or distributors, then you can know how much profits you will get by this machine.

> How much price of Garments Fabric Waste Press Machine Baling With Hydraulic Baler?

Price of the baler machine is different, depends on how big of the machine is, but we can give you a word that our price of the machine is lower with high quality.

> Which country have you exported the Press Baling Of Used Clothes In Belgium?

We have exported the baler machine to many countries such as Japan, Thailand, Malaysia, Singapore, Indonesia, India, Pakistan, Sri Lanka, Iraq, Iran , Qatar, Kuwait, Oman, Turkey, Finland, Sweden, Norway, Iceland, Denmark, Russia, Poland, Czech, Germany, Austria, Britain, Ireland, Netherlands, Belgium, France, Greece, Romania, Bulgaria, Albania, Slovenia, Croatia, Italy, Spain, Portugal, Egypt, Chile, Argentina, Ecuador, Canada, America, USA, Australia, New Zealand, South Africa, Mexico and other countries.

Hotline : +86 152 2134 7650

Hotline : +86 152 2134 7650 Email : info@diloya.com

Email : info@diloya.com

Product

Product Phone: +86 152 2134 7650

Phone: +86 152 2134 7650 E-mail: info@diloya.com

E-mail: info@diloya.com Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China

Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China