A Fully Automatic Horizontal Continuous Baling Press Machine is an industrial equipment designed for...

| Basic Infomation | |

Delivery Time: 30 Days Quality Control: ISO9001, 2008 Control: PLC Automatic Control Port: Shanghai Port Output Capacity: 12-20bales/Hour Lead Time: 15 Days Package: Wooden Package Color: Ral5013 or Per your requirement Status Of Machine: Totally New Model Series: MHC Series | Model Series: MHL Series Motor: China Famous Brand Packaging: Nude Packing/Wooden Package Bale Discharge Type: Continuous Push-Out Applicable Material: Paper/Pet Bottles Model Series: ABH Series Model Series:MHS Series Machine Weight:6000-25000kg Warranty Time: 1 Year Min. Order: 1 Set |

| Additional Information | |

Video Support: Yes Productivity: 30-50sets/Month Transportion: Ocean Shipping Certificate: CE TUV ISO | Motor Power: 4-45kw Trade Term: FOB CIF CNF Core Components: Pump, Motor Steel Plate: Q235B |

| Package And Delivery | |

Package: Wood package, Plastic Films, Nude Packing | Delivery: Ocean Shipping |

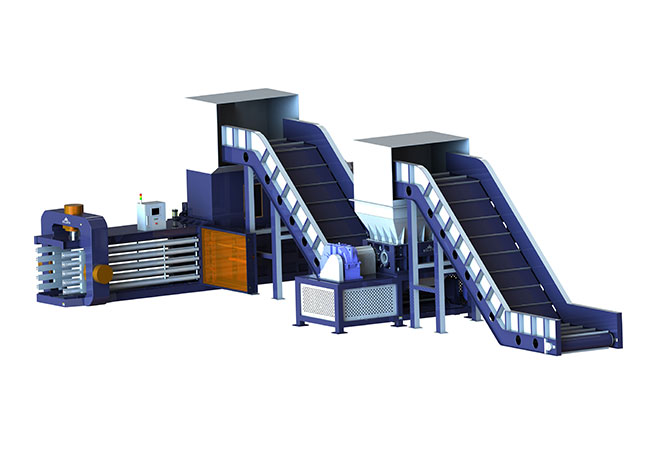

ABH Fully Automatic Horizontal Continuous Baling Press Machine mainly compress waste cardboard box, OCC, ONP, carton box, plastic scrap, PET bottles, plastic films, hay straw etc...

The ABH Series Fully Automatic Horizontal Continuous Baling Press Machine mainly used in cardboard paper manufacturer and many waste disposal recycling center, it is composed of three sections: hydraulic system, electrical system, main frame, can handle all kinds of paper scrap such as paper shredding, paper trimming, waste cardboard, OCC, ONP, etc...

Working Principle: The paper scrap is put into the box chamber by people or conveyor, then the main cylinder will press the paper scrap and other scrap to the limit several times which is set in our factory, and then the auto tying system will bundle the bale automatically, and the bale will be pushed out continuously by main cylinder, this way, the bale is finished completely, then start the next bale continuously.

A Fully Automatic Horizontal Continuous Baling Press Machine is an industrial equipment designed for the continuous compaction of materials into bales or blocks. This type of machine is widely used in recycling facilities, waste management centers, and industries that deal with large volumes of recyclable materials such as paper, cardboard, plastics, textiles, and other similar materials.

Key Features:

1. Horizontal Design: Unlike vertical balers, horizontal balers have a loading chamber where materials are fed horizontally. This design allows for easier handling of bulk materials.

2. Continuous Operation: These machines are capable of operating continuously, which increases productivity and efficiency compared to batch processing systems.

3. Automation: They feature automated processes for material feeding, compression, and ejection of bales. This reduces the need for manual labor and increases safety.

4. High Compression Ratio: They apply significant pressure to compress materials tightly, reducing their volume significantly and making them easier to store and transport.

5. Variable Pressure Control: The ability to adjust compression pressure ensures optimal results for different types of materials.

6. Bale Size Customization: Users can customize the size of the bales produced, depending on storage and transportation requirements.

7. Safety Features: Equipped with various safety mechanisms such as emergency stop buttons, safety interlocks, and protective guards to ensure operator safety.

8. Efficient Energy Use: Advanced hydraulic systems and control technologies help reduce energy consumption while maintaining high performance.

Applications:

- Recycling Facilities: For compacting materials like paper, cardboard, plastics, and metals.

- Waste Management: To handle municipal solid waste and other recyclables.

- Textile Industry: To compress textile scraps and fibers.

- Agriculture: For compressing straw, hay, and other agricultural products.

Benefits:

- Cost Efficiency: Reduces storage space requirements and lowers transportation costs.

- Environmental Impact: Helps in waste reduction and promotes recycling.

- Labor Savings: Automates the baling process, reducing the need for manual labor.

- Quality Output: Consistent and high-quality bales due to precise control over the compression process.

When choosing a Fully Automatic Horizontal Continuous Baling Press Machine, it's important to consider factors such as the type and volume of materials you will be processing, your production capacity needs, and the specific features that align best with your operational requirements.

Parameter

Model | Bale Size (mm) | Bale Weight (Kg) | Power (Kw) |

ABH40 | 720X800 | 200-350 | 18.5 |

ABH60 | 750X1100 | 400-700 | 22 |

ABH80 | 850X1100 | 500-800 | 37 |

ABH100 | 1100X1100 | 800-950 | 45 |

ABH125 | 1100X1250 | 900-1050 | 55 |

ABH160 | 1100X1250 | 1000-1250 | 37X2 |

ABH200 | 1100X1250 | 1200-1450 | 45X2 |

If you have any special requirements, we will customize according to your special needs.

Product Show

|  |

|  |

|  |

|  |

|  |

Advantage

1. Adopts horizontal structure with continuously push out type.

2. Automatic tying system includes auto-threading and auto-cutting system, no need people to watch it all the time.

3. Fully automatic control, high efficiency, save labor cost, transportation cost, stock cost and space.

4. Auto-counting system, convenient to manage production rate and record bale quantity

5. Bale length and bale weight can be adjustable according to your requirement.

6. Output capacity varies from 2 to 15tons per hour, more options for your choices.

7. Auto-inspecting system for waste scrap to start or stop the machine automatically, save power energy, easy to operate and maintain.

8. Adopts German hydraulic technology to promise the machine run smoothly, durable and reliable.

9. Adopts international brand of hydraulic pump and valves to prolong the service life of the baler machine.

Application

The baler machine can press below materials:

FAQ

> What is warranty time of the Top Load Kraft Paper Baling Machine?

The warranty time of the baler machine is 12 months normally, also can you can pay extra fees for more times such as 24 months or 36 months, within the warranty time, we are responsible for the baler machine except the spare parts.

> What all do I need to install the Fully Automatic Carton Box Packaging Machine?

After the vertical pet bottles baler machine arrived your place, you need the hydraulic oil, cable wire, worker, electrical technician, then you can start to test and operate the baler machine per user manual, or make video call with our engineer.

> What is How to Choose Occ Packaging Machine?

The baler machine is mainly used to compress paper box, pet bottles, plastic films into small bales with high density, easy to transport and stock, save transport cost, stack cost, convenient for distributor to sell to their end users.

> How can we install the Heavy Duty Corrugated Box Compressor Machine?

The baler machine is not disassembled when shipping, so you just put it on the horizontal ground, adding hydraulic oil, connect to the power supply, then test and operate the machine per user manual, that is OK, if you have any questions, you can contact with us any time.

> What is trade term of India Corrugated Box Compactor?

Trade term of the baler machine are FOB, CIF, CNF, these 3 terms, and we also can per your requirements.

> How can i know you are a manufacturer or trader of How to Operate Paper Trimings Recycling Baler?

You can visit our factory personally, also you can ask technical drawings such as 2D drawings 3D Drawings, we have professional technical team working on this, and will not give you these if a trader, because they don't have ability on this.

> What are all the skills required to operate a Latest Kraft Paper Packaging Machine manufactured by Diloya?

No special skills, just read the user manual carefully before operating the machine, if you have any questions, feel free to contact with us, we can help you at any time.

> What is after-services of Good Quality Cardboard Box Compress Baler?

We provide training and installation services, we can guide you how to install, test, use, operate and maintain the baler machine for free, which also include video support, email services, and in a word, we can get everything done.

> Where to find cheap Ce Approved Occ Paper Baling Machine?

You can search the key words which you want in the Google Search, then you will find many suppliers who have this kind of baler machine, then you need to make some comparisons of these suppliers, then you can find good supplier with lower prices.

Hotline : +86 152 2134 7650

Hotline : +86 152 2134 7650 Email : info@diloya.com

Email : info@diloya.com

Product

Product Phone: +86 152 2134 7650

Phone: +86 152 2134 7650 E-mail: info@diloya.com

E-mail: info@diloya.com Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China

Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China