HCMS Series Movable Metal Scrap Horizontal Container Shear Machine, mainly cut waste steel metal, an...

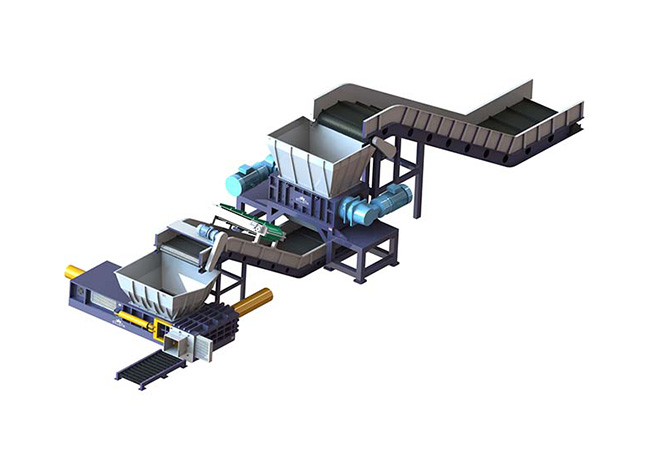

A Horizontal Waste Plastic Films Grids Cutter is a specialized machine designed for cutting waste plastic films into smaller, more manageable pieces or grids. This type of equipment is commonly used in recycling facilities and manufacturing plants to process large quantities of plastic film waste efficiently.

Here are some key features and considerations for such a cutter:

Key Features:

1. Horizontal Configuration:

- The machine operates on a horizontal plane, allowing for continuous feeding of the plastic film.

- This configuration can handle large rolls or sheets of plastic film.

2. Grid Cutting:

- The cutter is equipped with a grid-like arrangement of blades that cut the plastic film into uniform squares or rectangles.

- The size of the grids can often be adjusted based on the specific requirements.

3. Blades and Cutting Mechanism:

- High-quality, durable blades are used to ensure clean and precise cuts.

- The blades are typically made from materials like stainless steel or other wear-resistant alloys.

- The cutting mechanism may include a series of rotating or stationary blades, depending on the design.

4. Feeding System:

- An automated feeding system ensures that the plastic film is fed into the cutter at a consistent speed.

- Some machines may have a conveyor belt or roller system to guide the film through the cutting process.

5. Safety Features:

- Safety guards and emergency stop buttons are essential to protect operators.

- Some machines may also have sensors to detect any obstructions or issues during operation.

6. Control Panel:

- A user-friendly control panel allows operators to adjust settings, monitor the cutting process, and make necessary adjustments.

- Modern machines may include digital displays and programmable controls.

7. Material Handling:

- The machine should have a system for collecting and disposing of the cut plastic grids.

- This may include a collection bin or a conveyor system to transport the cut pieces to the next processing stage.

Applications:

- Recycling: The cut plastic grids can be further processed into pellets or other forms for reuse.

- Manufacturing: In industries where plastic film is a byproduct, the cutter can help manage and repurpose the waste.

- Agriculture: Cut plastic films can be used for mulching or other agricultural applications.

Considerations:

- Material Type: Ensure the cutter is suitable for the type of plastic film you are processing (e.g., polyethylene, polypropylene).

- Capacity: Choose a machine that can handle the volume of waste plastic film you need to process.

- Maintenance: Regular maintenance is crucial to keep the blades sharp and the machine running smoothly.

- Energy Efficiency: Look for energy-efficient models to reduce operating costs.

If you are looking to purchase or operate a Horizontal Waste Plastic Films Grids Cutter, it's important to consult with a supplier or manufacturer to get a machine that meets your specific needs. They can provide detailed specifications, training, and support to ensure the machine operates effectively and safely.

Parameter

Model | HAS100 | HAS150 | HAS200 | HAS300 |

Hydraulic Power | 100tons | 150tons | 200tons | 300tons |

Motor Power | 37kw | 2x22kw | 2x30kw | 2x37kw |

Final Size | <300mm | <300mm | <300mm | <300mm |

Grids Quantity | 9 | 12 | 15 | 15 |

Grid Size | 900x900mm | 1200x1200mm | 1500x1200mm | 1800x1200mm |

Machine Weight | 9860kg | 11350kg | 14260kg | 18560kg |

If you have any special requirements, we will customize according to your special needs.

Product Show

|  |

|  |

|  |

|  |

|  |

|  |

Advantage

1. Adopts latest design, easy to operate, install and maintain, more cutting pressure, high output capacity.

2. Cutting frequency can be up to 1 times per minute, more efficient, save labor cost, transportation cost and space.

3. Electrical button control with manual and auto model type, very easy to operate and maintain.

4. Output capacity varies from 5 to 15tons per hour, also can be customized per your requirement.

5. Adopts German Hydraulic technology to promise the machine run smoothly and stably.

6. Adopts international brand of hydraulic pump and valves to prolong the service life of the shear machine, durable and reliable.

7. Lower price, economical option for your business, it’s ideal shear machine for your choices.

Application

The cutter machine can cut below big bale:

FAQ

> How much price of Hydraulic waste film cutter?

Price of the cutter machine is different, depends on how big of the machine is, but we can give you a word that our price of the machine is lower with high quality.

> Is there any spare parts along with the agricultural film cutting machine?

Yes, we will provideo some spare parts for free which inlucdes tools, O Rings and some other electrical components like middle relay, and you need to pay extra cost for wear parts.

> What profits can we get from the Cutting waste films machine?

You need to know price of films waste, and price of the cutted film you sell to metal recycling center or plastic manufacturer, then you can know how much profits you will get by this machine.

> Are you a manufacturer or a trader of horizontal agricultural films cutter?

We are true manufacturer of waste films cutting machine, we have our own technical team, R&D team, have many processing machines, and you are warmly welcome to visit our factory personally.

> What is HS Code of Hydraulic Scrap films shear cutter?

Generally speaking, we use HS Code 8422400090 for the cutter machine, and we can use other HS Code per your convinience.

> How much would plastic waste films' its installation, and training cost me?

The price of cutter machine is different according to different plastic films scrap and output capacity as for the installation, training cost, the machine is very easy, just put it on horizontal ground, adding hydraulic oil, connect to power supply, then operate per user manuals.

> What is warranty term of the Hydraulic waste films cutter?

Within the guarantee period, in the event of any malfunction caused by the quality of the commodity, we provide free components for replacement. Wear parts are exclusive from this warranty. We also provide technical support for the whole lifespan of the machine.

> What is voltage of China horizontal grids cutter for plastic films?

For the voltage of the machine, no need to worry about that, we will customize the motor per your local voltage and frequency, and the important thing that the shear machine must need 3 phases electrical power supply.

Hotline : +86 152 2134 7650

Hotline : +86 152 2134 7650 Email : info@diloya.com

Email : info@diloya.com

Product

Product Phone: +86 152 2134 7650

Phone: +86 152 2134 7650 E-mail: info@diloya.com

E-mail: info@diloya.com Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China

Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China