GZC Series Heavy Plastic Scrap Granulator Machine, mainly gr...

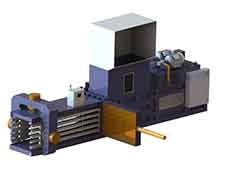

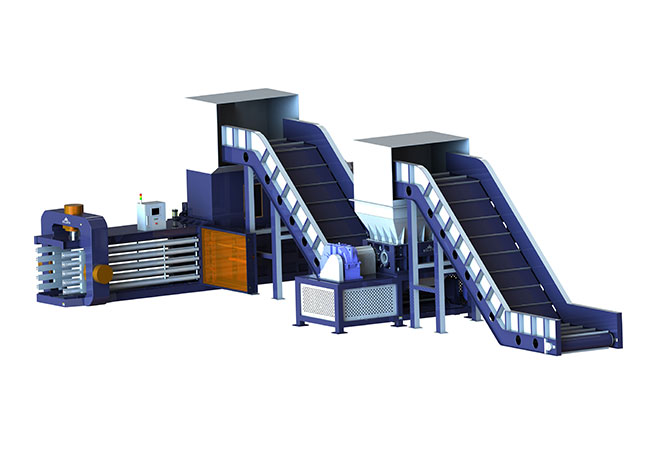

An automatic continuous palm fiber baling machine is a specialized piece of equipment designed to compress and bundle palm fibers (such as those from oil palms or coconut palms) into consistently sized and shaped bales for easy handling, transportation, and storage. These machines play a crucial role in the palm fiber processing industry, helping to streamline operations and improve efficiency.

Key features and components of an automatic continuous palm fiber baling machine typically include:

1. Feeding System: This part of the machine receives raw palm fibers and feeds them into the compression chamber. It may include conveyors, hoppers, or other mechanisms to ensure a steady flow of material.

2. Compression Chamber: The heart of the machine where the palm fibers are compressed using hydraulic or mechanical forces. The compression process helps reduce the volume of the material, making it easier to handle and store.

3. Binding Mechanism: Once the fibers are compressed to the desired density, they are bound with straps or ties to maintain their shape during handling and transport. This can be done automatically by the machine.

4. Control System: Modern baling machines often feature advanced control systems that allow operators to adjust settings such as compression force, bale size, and binding parameters. Some models may even offer programmable logic controllers (PLCs) for more sophisticated automation.

5. Output System: After the bales are formed and bound, they are discharged from the machine. This could involve a conveyor system or other means of moving the finished bales to a designated area.

6. Safety Features: To protect operators and ensure smooth operation, these machines often come equipped with safety interlocks, emergency stop buttons, and other protective measures.

Benefits of using an automatic continuous palm fiber baling machine include:

- Increased Efficiency: Continuous operation reduces downtime between batches, leading to higher productivity.

- Consistent Quality: Automated processes help maintain consistent bale sizes and densities.

- Reduced Labor Costs: Less manual intervention required, lowering labor costs.

- Improved Safety: Automation minimizes the risk of workplace injuries associated with manual handling of bulky materials.

- Enhanced Storage and Transportation: Smaller, denser bales take up less space and are easier to transport compared to loose fiber.

When selecting an automatic continuous palm fiber baling machine, it's important to consider factors such as production capacity, bale dimensions, power requirements, and any specific needs related to the type of palm fiber being processed.

The Jute Balling Press Machine Price is mainly compress the sisal fiber, coir fiber, and other natural fibers into small bales with high density, easy to transport, stock and save labor cost, make more money, it has other names such as Hydraulic Press For Abaca Fiber,Sisal Fiber Baler Machine,Sisal Bale Press Machine,Plant Fiber Hydraulic Press,How To Compress Jute,Hot Sale Hydraulic Hemp Sisal Fiber Baler Packing Machine,Sisal Baling Machine,Coconut Fiber Bailing Unit,Sisal Presing Machine.

Applicable Machine

Please find below baler machine for palm fiber:

We not only have these baler machine, but have other machines such as CSJ baler High Quality Copper Drillings briquetting machine, UT Machinery Suzhou Hard Plastic Lumps Shredder , Russia 10lb Cleaning Rags Packing Machine, Enerpat baler Wood Sawdust Press Baler, Hello baler Conveyor Belt Cardboard Box Recycling Baler, Romania CE Jumbo Bags Single Axle Shredder, Iceland China Aluminum Scrap Baler, Huicheng Mobile Scrap Metal Alligator Cutter, Finland Hydraulic Jute Fiber Packing Machine, Norway Semi-Automatic Pet Bottles Bale Machine , Sri Lanka 125Ton Steel Scrap Compactor, Bulgaria 250Ton Steel Plate Crocodile Shear, Ecuador Y83 Aluminum Millings baling machine, Poland China Marine Use Compactor, Mexico Automatic Brass Powder briquetter, Sweden Industrial Wiping Cloth Compressor Machine, Netherlands 150kg Jute Fiber Baler Press Machine, Belgium Wipers cuting and packaging, Sino baler Rags bagging press machine, Croatia Automatic Scrap Metal Compactor, Malaysia Automatic Metal Scrap Shredder, SK baler 100kg Second Hand Clothes Baling Press, Pakistan Hydraulic Iron Metal Pressing Machine, Spain Cost of Computer Disks Dual Shaft Shredder, Turkey Cutting Machine For Metal Scrap, Australia 50kg Grass Silage Bagging Press Machine, XT baler Cheap Price Blue Barrels Recycling Shredder, Austria 250kg Kenaf Fibre Compactor Machine, Slovenia High Speed Alu Cans Tins Baling Press, Italy 200kg Sisal Compactor Machine, Nantong supplier Automatic PE Barrels Shredder, Chile SBJ Aluminum Drillings baling machine, Ireland Strong PE Barrels Double Shaft Sharedder, Qatar Cheap Price Hard Disks Twin Shaft Shredder, America SBJ Copper Swarfs briquetting press, New Zealand Latest Newspaper Packing Machine, Canada Hydraulic Scrap Steel Shears, Argentina Chopped Straw Animal Feedings Compressor, Jiangsu supplier, Low Cost Paper Tube Shredder Crusher, CSJ baler Powerful PP Raffia Bags Single Shaft Shredder etc...

Please contact with us if you have any questions.

Effect

Please find below pictures of palm fiber:

|

|

|

|

|

|

|

|

FAQ

> How can i know you are a manufacturer or trader of Bales Of Jute Fibre?

You can visit our factory personally, also you can ask technical drawings such as 2D drawings 3D Drawings, we have professional technical team working on this, and will not give you these if a trader, because they don't have ability on this.

> What is trade term of High Density Sisal Compactor?

Trade term of the baler machine are FOB, CIF, CNF, these 3 terms, and we also can per your requirements.

> How to choose your Vertical Coconut Fiber Baling Press correctly?

As for this issues, first, you need to know which model of the baler machine will you need, then you can compare price, quality, services of the baler machine from different suppliers, and at last you will know which supplier is better.

> How do I decide the model of High Density Sisal Fiber Baler Press Machine that I need?

First, you need to know what bale size and bale weight are popular in your local market, then you produce the bale weight and bale size, and we can suggest you suitable model of wiper baler machine accordingly, Before this, you need to make investigation in your market, you can inquire your end user etc..

> Do you have a agent of 100kg Kenaf Fibre Baling Press in our country?

No, we don't have agent or representative in your country, we directly export the machine to our end users, this way, the price will be lower, and end users can get more money.

> What is package of Coco Coir Fibre Press Machine?

Generally speaking, there are two packages of the machine, wooden package, and plastic films, wooden package is mainly for small machine with LCL shipment, and plastic films mainly for big machine with FCL shipment.

> What are all the skills required to operate a 150kg Kenaf Fiber Compactor manufactured by Diloya?

No special skills, just read the user manual carefully before operating the machine, if you have any questions, feel free to contact with us, we can help you at any time.

> What all do I need to install the China Supplier Kenaf Fiber Baling Machine?

After the sisal fiber press machine arrived your place, you need the hydraulic oil, cable wire, worker, electrical technician, then you can start to test and operate the baler machine per user manual, or make video call with our engineer.

> How much price of Good Quality Jute Fiber Baling Press?

Price of the baler machine is different, depends on how big of the machine is, but we can give you a word that our price of the machine is lower with high quality.

Hotline : +86 152 2134 7650

Hotline : +86 152 2134 7650 Email : info@diloya.com

Email : info@diloya.com

Product

Product Phone: +86 152 2134 7650

Phone: +86 152 2134 7650 E-mail: info@diloya.com

E-mail: info@diloya.com Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China

Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China