GZC Series Heavy Plastic Scrap Granulator Machine, mainly gr...

An aluminum shavings briquetting press is a machine used to compress and form aluminum shavings, chips, or turnings into dense, compact briquettes.

This process offers several benefits for aluminum recycling and processing:

1. Increased density: Reduces the volume of material by 8-10 times.

2. Improved handling and storage: Easier to transport and store compared to loose shavings.

3. Reduced oxidation: Minimizes exposure to air, reducing oxidation and loss of material value.

4. Energy savings: Allows for more efficient melting when recycled.

5. Cost savings: Reduces transportation costs and increases the value of the material.

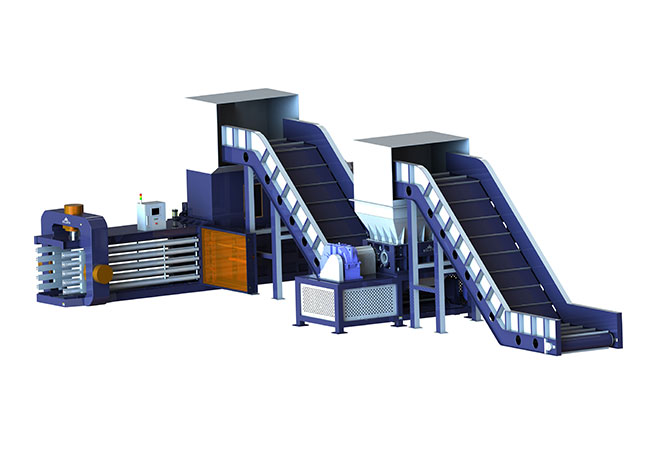

Key components of an aluminum shavings briquetting press typically include:

1. Feeding system: To introduce the aluminum shavings into the press.

2. Compression chamber: Where the material is compressed.

3. Hydraulic system: Provides the force to compress the material.

4. Control panel: For operating and adjusting the machine.

5. Briquette ejection mechanism: To remove finished briquettes from the press.

Types of aluminum shavings briquetting presses:

1. Horizontal presses: Common in smaller operations.

2. Vertical presses: More common in larger industrial settings.

3. Cold briquetting presses: Operate at room temperature.

4. Hot briquetting presses: Heat the material during compression (less common for aluminum).

Maintenance considerations: - Regular lubrication of moving parts - Inspection of hydraulic fluids - Cleaning of compression chamber - Replacement of worn components

When selecting a briquetting press, important factors to consider include:

- Production capacity needed - Material type and characteristics - Available floor space - Power requirements - Desired briquette size and shape

Properly implemented, an aluminum shavings briquetting system can significantly improve the efficiency and profitability of aluminum recycling operations while reducing environmental impact.

The Small Metal Chip Briquetting Machines is mainly compress the metal chips, aluminum chips, brass chips, bronze shavings, aluminum shavings into small bales with high density for metal manufacturer to remlelt again, easy to transport, stock and can highly improve the rate of melting, can make more profits, it has other names such as Latest Design Metal Chip Briquetting Press,Copper Chips baling machine,Metal Chips Briquetting Presses With Ce,Aluminium Shaving Briquettes Machine,Hydraulic Scrap Copper Iron Aluminum Chip Press Machine,Copper Powder Briquetting machine,Briquetting Machine Pre Compression For Aluminium,Metal Chips Briquette Machine In Pakistan,Quality Scrap Metal Copper Chip Briquetting Press.

Applicable Machine

Please find below briquetting press machine for aluminum chips:

We not only have these baler machine, but have other machines such as Dongfang hydraulic The Small Metal Chip Briquetting Machines is mainly compress the metal chips, aluminum chips, brass chips, bronze shavings, aluminum shavings into small bales with high density for metal manufacturer to remlelt again, easy to transport, stock and can highly improve the rate of melting, can make more profits, it has other names such as Latest Design Metal Chip Briquetting Press,Copper Chips baling machine,Metal Chips Briquetting Presses With Ce,Aluminium Shaving Briquettes Machine,Hydraulic Scrap Copper Iron Aluminum Chip Press Machine,Copper Powder Briquetting machine,Briquetting Machine Pre Compression For Aluminium,Metal Chips Briquette Machine In Pakistan,Quality Scrap Metal Copper Chip Briquetting Press., Iceland India Tins Cans Baling Press, Denmark Y81T Light Metal Baling Press, Huahong baler 500Ton Scrap Metal Crocodile Shear, Tianfu baler Heavy Duty Waste Steel Compactor, Gaode baler, Integrated Copper Scrap Alligator Shear, Slovenia Fast Aluminum Tins Compress Baler, Poland 160Ton Steel Scrap Alligator Shear, Chile Y83 Bronze Borings baling machine, Ecuador Y81Q Steel Scrap Compactor Machine, Pakistan SBJ Bronze Powder briquette machine, Thailand Fast Pop Cans Baling Press, Egypt Heavy Duty Metal scrap Compactor, Eco hydraulic Automatic Vertical briquetting press for bronze shavings, Bulgaria Small Ring-Pull Cans Compress Baler, Japan 250Ton Light Metal Press Baler, America Automatic Hydraulic block making machine for bronze shavings, Jiangyin supplier High Density steel Powder briquetting press, Wanshida baler Big Steel Wire Baler, Romania Metal Chips Briquetting Presses With Ce, Iraq Automatic briquette machine for Steel swarfs, Mexico Hydraulic briquetting machine for Steel drillings, India Y83 Bronze chips block making machine, Norway High Density Vertical briquetter for bronze swarfs, Italy High Density Hydraulic block making machine for Copper powder, Turkey Automatic metal Shavings baling machine, Ruf briquetting press High Density Vertical briquetter for Copper borings, Qatar Forward Out Scrap Metal Compress Baler, Portugal Two Ram Copper Scrap Recycling Baler, Jiangyin manufacturer Push Out Scrap Metal Press Baler, Shengbo baler Factory Price Steel Drillings briquetter, New Zealand Small Pop-Top Cans Recycling Baler, Indonesia Mobile shear scrap metal shear at work, Sweden China Bronze Swarfs baler, Australia Factory Price Stainless Steel sawrfs block making machine, Croatia 160Ton Round Bar Crocodile Shear, Spain Factory Price Bronze Millings briquetting press, Argentina Hopper Feed Aluminum Scrap Baler, Russia 160Ton Steel Scrap Cutter Machine, France Hydraulic briquette machine for Aluminum turnings etc...

Please contact with us if you have any questions.

Effect

Please find below pictures of copper cloves scrap:

|

|

|

|

|

|

|

|

FAQ

> What is payment term of Briquetting Machine Metal Powder?

The payment of the briquetting press machine is 30% TT as deposit, and 70%TT balance paid 7 days before shipment, and LC is also acceptable, it is flexible depends on amount of the machine.

> How can i know you are a manufacturer or trader of Y83-3150 Cast Iron Briquette Press Scrap Copper Chip Briquette Press?

You can visit our factory personally, also you can ask technical drawings such as 2D drawings 3D Drawings, we have professional technical team working on this, and will not give you these if a trader, because they don't have ability on this.

> How to maintain Briquetting Press for Powder Aluminum Alus pan Chips?

When you were operating the machine, you need to clean the oil tank every 3 months, and check the wire, and oil pipe leakage or not, and also check the bolt every shift, you can find all maintenance items in the user manual.

> Do you have a customer case of Bronze Powder Briquetting machine in our country for our reference?

We have many customers over the world, and one issue that we all signed the secret agreement with our customers, and then are not wiling to let other customers to visit their machines, as we all know, Peers are enemies.

> Do you provide video support of Cast Iron Chips Briquetting Press?

Yes, of course, we are providing the video support which includes installing the baler machine, testing and operating the machine, we also can guide you to replace parts and maintenance via video call.

> How do I decide the model of Iron Powder Briquette Machine Scrap Aluminum Chip Briquetting Press that I need?

First, you need to know what bale size and bale weight are popular in your local market, then you produce the bale weight and bale size, and we can suggest you suitable model of briquetting press machine accordingly, Before this, you need to make investigation in your market, you can inquire your end user etc..

> What is warranty time of the Brass Powder briquetter?

The warranty time of the briquetting press machine is 12 months normally, also can you can pay extra fees for more times such as 24 months or 36 months, within the warranty time, we are responsible for the baler machine except the spare parts.

> How much would Baling Steel Shavings Briqutte Press , its installation, and training cost me?

The price of baler machine is different according to different bale size, bale weight and output capacity as for the installation, training cost, the machine is very easy, just put it on horizontal ground, adding hydraulic oil, connect to power supply, then operate per user manuals.

Hotline : +86 152 2134 7650

Hotline : +86 152 2134 7650 Email : info@diloya.com

Email : info@diloya.com

Product

Product Phone: +86 152 2134 7650

Phone: +86 152 2134 7650 E-mail: info@diloya.com

E-mail: info@diloya.com Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China

Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China