GZC Series Heavy Plastic Scrap Granulator Machine, mainly gr...

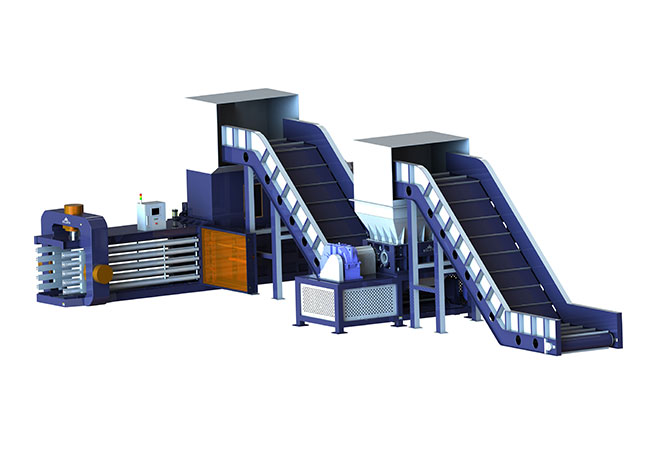

A Copper Tube/Pipe Scrap Baling Press Machine is a specialized piece of equipment used for compressing and compacting copper tubes or pipes into dense, manageable bales or blocks. This type of machine is commonly used in metal recycling facilities, scrap yards, and manufacturing plants to process copper waste materials efficiently.

Here are some key aspects of these machines:

1. Purpose: - Compresses copper tubing and pipes into compact bales - Reduces volume for easier handling, storage, and transportation - Facilitates recycling and reuse of copper scrap

2. Main components: - Hydraulic system for compression - Metal chamber or die - Punch or plunger - Control panel - Safety features (e.g., safety cages, emergency stop buttons)

3. Operation: - Feeds copper tubes/pipes into the machine - Compresses material using hydraulic pressure - Forms bales of consistent size and density - Ejects completed bale once it reaches desired size

4. Key features: - Adjustable bale size and density settings - High compression force for efficient processing - Quick cycle times for increased productivity - Durable construction for long service life - User-friendly control systems

5. Benefits: - Significantly reduces material volume - Increases storage capacity - Lowers transportation costs - Improves overall recycling efficiency

6. Applications: - Metal recycling centers - Scrap yards - Manufacturing facilities with copper tube/pipe waste - Construction sites generating copper scrap

7. Considerations: - Proper training for operators - Regular maintenance to ensure optimal performance - Compliance with safety regulations

8. Variants: - Manual, semi-automatic, or fully automatic models - Different sizes and capacities to suit various needs - Custom configurations for specific applications

When selecting a Copper Tube/Pipe Scrap Baling Press Machine, it's important to consider factors such as production requirements, available space, budget, and specific application needs. Consulting with manufacturers or experienced dealers can help determine the best solution for your particular situation."

The Stainless Sheet Metal Hydraulic Press Machine is mainly compress the waste cans tins, ubc cans, stainless steel scrap, metal chips, mixed aluminum scrap into small bales with high density for steel manufacturer to remelt again, it is easy to transport, stock, can improve the rate of steel melting , it has other names such as Hydraulic Press Scrap Metal baler machine,Scrap metal Baler Machine Pakistan,Stainless Steel Compressor Machine,Stainless Steel Baling Press Machine,Heavy Metal Scrap Baling Machine,Horizontal Metal Baler,How To Bale Scrap Tin,Scrap Metal 500 Tons Presser machine,Hydraulic Scrap metal Press Machine.

Applicable Machine

Please find below machine for copper tube pipe scrap:

| CMS Shear Baler | CM Push-Out Baler | FM Turn-Out Baler | QM Forward-Out Baler |

|  | ||

| DFM Middle Turn out Baler | PCM Pre-Load Baler |

We not only have these baler machine, but have other machines such as Greece Hydraulically Operated Chips Compactor Machines,America Iron Powder Briquettes Machine In India,Qatar Scrap Metal Pressing Machines,Spain SBJ Aluminum powder block making machine,Romania Vertical briquetter for Steel shavings,Chile High quality Copper Shavings baler,Canada China aluminum Shavings briquetter,Russia Low cost metal Swarfs briquetting press,Ruf briquetting press Automatic Ring-Pull Cans Baling Press,South Africa Factory price Bronze Chips baling machine,Oman High Quality Copper Drillings briquetter,Finland Y83 briquetting machine for Steel borings,Sweden China Copper Drillings briquette machine,Enerpat baler China steel Shavings briquette machine,Egypt Container Shear Enerpat,New Zealand Y83 briquetting machine for Aluminum swarfs,France Small Aluminum Scrap Crocodile Shear,Belgium Hopper Feed Aluminum Scrap Packing Baler,Norway China Ring-Pull Cans Baler With Conveyor,Poland Hopper Feed Tinplate Baler With Conveyor,Japan Vertical Bronze Swarfs baling machine,Iraq Container Shear/Horizontal Shear,Aupu machinery baler Aluminum Cans Baler,Pakistan Shredded Iron Scrap Briquetting Making Machine,Tianfu baler Small UBC Baler,Turkey Powerful Steel Scrap Baling Press,Mexico High Quality Stainless Steel Drillings briquetting machine,Kuwait Low cost Copper Swarfs briquetting machine,Chuangda baler Horizontal Hydraulic Press For Metal Scrap,Ireland Horizontal Press Steel Bar Shear,Gaode baler, Automatic Hydraulic briquetting press for brass turnings,Wanshida baler Factory price Copper Chips briquette machine,Italy China Brass Swarfs briquetting machine,Dongfang hydraulic 315Ton Steel Wire Cutter Machine,Denmark Automatic Hydraulic Alligator Shear,Huahong baler Automatic Hydraulic briquetting press for brass chips,Ecuador 315Ton Waste Steel Compactor Machine,India Low Cost Cast Iron Millings briquetting press,Portugal China Supplier Alu Cans Tins Baler With Conveyor,Bulgaria High Quality Steel Millings briquetting machine etc...

Please contact with us if you have any questions.

Effect

Please find below pictures of aluminum wire scrap:

|

|

|

|

FAQ

> Does the installation of Steel Scrap Packing Machine require drilling and bolting into the floor or can stand without drilling?

Regarding the drillings or not, it depends on the type of baler machine, for vertical baler machine, most of vertical baling machine needs drilling and bolting, because it is vertical type, and weight center of the machine is high; and for horizontal baler, it no need foundation, drilling and bolting, just put it on horizontal cement gound wich thickness more than 150mm.

> Is it possible to change the wear plate on Small Scale Aluminum Scrap Press Machines?

We have two method to fix the wear steel plate, one is welding the wear plate on the baler machine, and another type is changeable, whichever type of fixing, we can do it per your special requirement.

> Are the interchangeable wear plate installed on Scrap Metal Compactor For Sale?

Yes, the wear steel plate is changeable, you can easily change it when which wear plate is going to change, and we also can weld the wear plate directly, because this way, it is durable ans stable.

> What is the delivery time of Metal scrap Press Machine Pakistan?

The delivery time of the baler is different according to different models, and also according to our production plan, any way, we will try our best to finish the machine as early as possible.

> Is it automatic or Manual control for Steel Bar Packing Machine?

The baler machine has automatic control and manual control, the manual control is used to debug the machine when the baler machine arrived at your place, and the machine will run in automatic control when normal working, and that will be more efficient in automatic control.

> What is Steel scrap Press Compactor Machine?

The baler machine is mainly used to compress light metal scrap, stainless steel scrap, aluminum scrap, waste tins cans etc into small bales with high density, easy to transport and stock, save transport cost, stack cost, convenient for recycling center or steel manufacturer to melt again, improve the rate of steel melting.

Hotline : +86 152 2134 7650

Hotline : +86 152 2134 7650 Email : info@diloya.com

Email : info@diloya.com

Product

Product Phone: +86 152 2134 7650

Phone: +86 152 2134 7650 E-mail: info@diloya.com

E-mail: info@diloya.com Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China

Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China