Scraping a compressor for recycling metals is a valuable and environmentally responsible practice. C...

| Basic Infomation | |

Feeding Type:Moible Bin; | Payment Term:T/T L/C; |

| Additional Information | |

Working Pressure:21.5Mpa; | Chamber Length:1200-2500mm; |

| Package And Delivery | |

Package: Wood package, Plastic Films, Nude Packing | Delivery: Ocean Shipping |

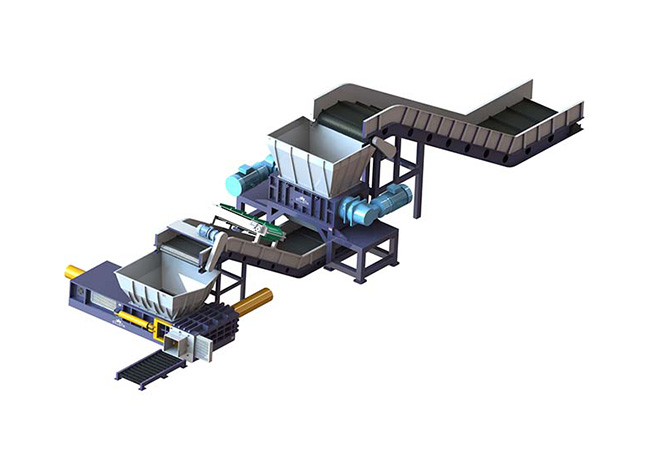

A 200-ton scrap metal press baler is a heavy-duty machine used in the recycling and scrap metal industry to compress and form scrap metal into compact, manageable bales. This process makes it easier to transport and store the scrap metal, as well as prepare it for further processing or sale.

Key Features and Components:

1.Pressing Force: -The 200-ton pressing force indicates the maximum pressure the machine can apply to compress the scrap metal. This is typically achieved through a hydraulic system that uses a combination of pistons, cylinders, and hydraulic fluid to generate the necessary force.

2.Hydraulic System: -The hydraulic system is the heart of the baler. It includes a pump, motor, valves, and cylinders. The pump pushes hydraulic fluid through the system, which then actuates the cylinders to apply the pressing force.

3.Chamber: -The chamber is where the scrap metal is loaded and compressed. It is designed to withstand the high pressures generated by the hydraulic system. The chamber may have different sizes and shapes depending on the specific requirements of the operation.

4.Control Panel: -The control panel allows the operator to control the machine's functions, such as starting and stopping the press, adjusting the pressing force, and monitoring the machine's status. Modern balers often include digital displays and programmable settings.

5.Safety Features: -Safety is a critical aspect of operating a 200-ton scrap metal press baler. Common safety features include emergency stop buttons, safety interlocks, and protective guards to prevent accidents.

6.Bale Ejection: -Once the scrap metal is compressed into a bale, the baler must be able to eject the bale safely and efficiently. This is typically done using a hydraulic ejection system or a mechanical pusher.

7.Material Handling: -Some balers come with integrated material handling systems, such as conveyors or cranes, to load and unload the scrap metal from the chamber.

Applications:

-Recycling Centers:

-Scrap metal balers are commonly used in recycling centers to process and prepare scrap metal for recycling.

-Scrap Yards:

-Scrap yards use balers to compact and bale scrap metal, making it easier to transport and sell.

-Manufacturing Facilities:

-Manufacturing facilities that generate scrap metal as a byproduct of their operations may use balers to manage and dispose of the scrap efficiently.

Benefits:

-Space Efficiency: -Compressing scrap metal into bales significantly reduces the space required for storage and transportation.

-Cost Savings: -By reducing the volume of scrap metal, transportation costs are lowered, and more material can be transported in a single load.

-Environmental Impact: -Efficiently managing and recycling scrap metal helps reduce waste and contributes to environmental sustainability.

Maintenance and Care:

-Regular Inspections: -Regular inspections of the hydraulic system, electrical components, and structural integrity are essential to ensure the baler operates safely and efficiently.

-Lubrication: -Proper lubrication of moving parts, such as cylinders and pistons, is crucial to prevent wear and tear.

-Training: -Operators should be trained on the safe and proper use of the baler, including how to perform routine maintenance and handle emergencies.

If you have any specific questions or need more detailed information about 200-ton scrap metal press balers, feel free to ask

Parameter

Model | CM125 | CM160 | CM200 | CM250 | CM315 |

Chamber Size(mm) | 1200x700x600 | 1600x1200x800 | 1800x1400x900 | 2000x1400x1000 | 2500x2000x1200 |

Bale Size(mm) | 300x300mm | 400x400mm | 450x450mm | 500x500mm | 600x600mm |

Bale Weight(kg) | 40-70kg | 80-150kg | 130-200kg | 200-300kg | 250-400kg |

Power(mm) | 15kw | 22kw | 30kw | 2x22kw | 2x37kw |

Machine Weight(kg) | 6250kg | 11540kg | 19840kg | 24580kg | 28420kg |

Machine Size(mm) | 4250x2180x1980 | 4780x2560x2150 | 5140x2920x2360 | 5280x2990x2650 | 7380x3850x3260 |

If you have any special requirements, we will customize according to your special needs.

Product Show

|  |

|  |

|  |

|  |

Advantage

> Adopts simple structure, easy to operate and maintain.

> Strong structure of the machine, reliable, stable and durable, let you make more money.

> Long warranty time of the baler machine, you are no need to worry about the after-services.

> One Button automatic PLC Control, just need to push one button, you can operate the machine continuously.

> Output capacity can be up to 20-30bales per hour, more efficient.

> World famous brand of Siemens PLC to promise you run the machine without any worry.

> Schneider electrical components prolong the service life of the machine.

> Lifelong after services let you have no any concern, get more porfits.

Application

The baler machine can press below materials:

|  |  |  |

| Aluminum cans tins | Light Metal Scrap | Copper Tube/Pipes | Coppe Wire Scrap |

|  |  |  |

| Aluminum Extrusion Profiles | Stainless Steel Scrap | Lead Strips | Aluminum Shavings |

|  |  |  |

|  |  |  |

FAQ

> How to operate Metal scrap Press Machine Pakistan?

This baler is very simple, just operate per user manual is ok, you can contact with us if you have any questions any time, we can guide you how to operate the baler machine.

> What is the electricity supply of Automatic Baler for Scrap metal needed, single or three phase?

The electricity supply of the machine is 3 phases, for the voltage, we can customzie the motor voltage per your local voltgage.

> What bale size does the Non Ferrous Metal Scrap Baler Machine produce?

We can customize the bale size per your requirement, also you can tell us your requirement, we can suggest you suitable bale size accordingly.

> What all do I need to install the Aluminum Scrap Baler At Aluminum Extrusion Plant?

After the metal scrap baler machine arrived your place, you need the hydraulic oil, cable wire, worker, electrical technician, then you can start to test and operate the baler machine per user manual, or make video call with our engineer.

> What is warranty term of the Heavy Duty Scrap metal Baling Press?

Within the guarantee period, in the event of any malfunction caused by the quality of the commodity, we provide free components for replacement. Wear parts are exclusive from this warranty. We also provide technical support for the whole lifespan of the machine.

> Do you have a customer case of Scrap Metal Compactor machine For Sale in our country for our reference?

We have many customers over the world, and one issue that we all signed the secret agreement with our customers, and then are not wiling to let other customers to visit their machines, as we all know, Peers are enemies.

> Do you provide video support of Small Metal Baler For Sale?

Yes, of course, we are providing the video support which includes installing the baler machine, testing and operating the machine, we also can guide you to replace parts and maintenance via video call.

Hotline : +86 152 2134 7650

Hotline : +86 152 2134 7650 Email : info@diloya.com

Email : info@diloya.com

Product

Product Phone: +86 152 2134 7650

Phone: +86 152 2134 7650 E-mail: info@diloya.com

E-mail: info@diloya.com Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China

Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China