Scraping a compressor for recycling metals is a valuable and environmentally responsible practice. C...

| Basic Infomation | |

Lead Time: 15 Days; | Package: Plastic Films/Nude Package; |

| Additional Information | |

Cycle Time: 30-60 Seconds/Bale; | Supply Ability: 50-100sets/Month; |

| Package And Delivery | |

Package: Wood package, Plastic Films, Nude Packing | Delivery: Ocean Shipping |

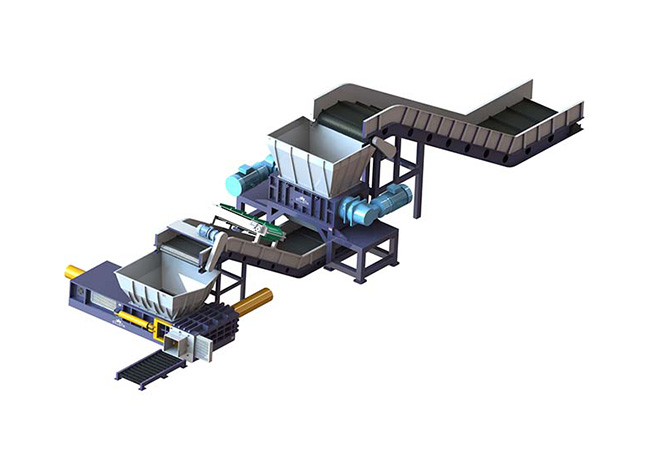

A metal scrap shearing and baling machine is a piece of equipment used in the recycling industry to process and prepare metal scrap for efficient transportation, storage, and further processing.

This type of machine typically combines two main functions: shearing and baling.

Key Components and Functions

1. Shearing Mechanism:

- Purpose: To cut and reduce the size of large pieces of metal scrap.

- Operation: The shearing mechanism uses powerful hydraulic or mechanical systems to cut through metal. It can handle various types of metals, including steel, aluminum, and copper.

- Blades: High-strength, wear-resistant blades are used to ensure effective cutting and long service life.

2. Baling Mechanism:

- Purpose: To compress and bind the sheared metal scrap into compact, manageable bales.

- Operation: After shearing, the metal pieces are fed into a compression chamber where they are compressed using hydraulic pressure. The baled metal is then tied with wire or straps to maintain its shape.

- Output: The resulting bales are uniform in size and density, making them easier to handle, transport, and store.

Benefits

- Efficiency: Reduces the volume of metal scrap, making it more economical to transport and store.

- Cost Savings: Minimizes transportation costs by reducing the number of trips required to move the same amount of material.

- Environmental Impact: Promotes recycling and reduces the need for raw materials, contributing to environmental sustainability.

- Safety: Properly baled and sheared metal is safer to handle and less likely to cause accidents during transportation and processing.

Applications

- Recycling Centers: Used to process and prepare metal scrap for recycling.

- Scrap Yards: Helps in managing and preparing metal scrap for sale or further processing.

- Manufacturing Plants: Can be used to manage and recycle metal waste generated during production processes.

Considerations When Choosing a Machine

- Capacity: Ensure the machine can handle the volume and type of metal scrap you need to process.

- Power Source: Determine whether a hydraulic, electric, or diesel-powered machine is most suitable for your needs.

- Maintenance: Consider the ease of maintenance and availability of spare parts.

- Safety Features: Look for machines with safety features such as emergency stop buttons, guarding, and interlocks to protect operators.

Conclusion

A metal scrap shearing and baling machine is an essential tool for any facility dealing with metal recycling. By efficiently shearing and baling metal scrap, these machines help streamline operations, reduce costs, and promote environmental sustainability. If you have specific requirements or need more detailed information, feel free to ask!

Video

Parameter

Model | Box Size (mm) | Bale Size (mm) | Bale Weight (Kg) | Power (Kw) |

CMS125 | 1400X900X300 | 300X300 | 40-70 | 37 |

CMS160 | 1500X1000X350 | 350X350 | 70-120 | 30x2 |

CMS200 | 1800X1400X400 | 400X400 | 120-180 | 37x2 |

CMS315 | 2000X1400X500 | 500X500 | 120-250 | 37X3 |

If you have any special requirements, we will customize according to your special needs.

Product Show

|  |  |  |

|  |  |  |

|  |  |  |

|  |  |  |

Advantage

> Output capacity can be up to 30-60bales per hour, more efficient.

> One Button automatic PLC Control, just need to push one button, you can operate the machine continuously.

> Enough spare parts with lower cost to keep the machine non-stop.

> Long warranty time of the baler machine, you are no need to worry about the after-services.

> Adopts simple structure, easy to operate and maintain.

> Latest design of the machine to let you use the best the machine all the time.

> Adopts china famous pump to keep baler machine run smoothly.

Application

The baler machine can press below materials:

|  |  |  |

| Aluminum cans tins | Light Metal Scrap | Copper Tube/Pipes | Copper Turnnings |

|  |  |  |

| Aluminum Extrusion Profiles | Stainless Steel Scrap | Lead Strips | Aluminum Shavings |

|  |  |  |

| Bronze Chips | Brass Chips | Steel Turnings | Aluminum Turnings |

|  |  |  |

|  |  |  |

FAQ

> Is there any spare parts along with the Stainless Sheet Metal Compression Baler Machine?

Yes, we will provideo some spare parts for free which inlucdes tools, O Rings and some other electrical components like middle relay, and you need to pay extra cost for wear parts.

> Before shipment, can you take testing video of Aluminium Cans Baler With Conveyor?

Yes, of course, we not only can take a video of machine running before shipment, we also can take videos, photos of the process of manufacturing the baler for you.

> How can we install the Aluminum Scrap Compactor Machine?

The baler machine is marked tips when shipping, and you can easily assemble the machine per the tips, after assembling, put it on the horizontal ground, adding hydraulic oil, connect to the power supply, then test and operate the machine per user manual, that is ok, if you have any questions, you can contact with us any time.

> What is after-services of Pop Can Baling Press?

We provide training and installation services, we can guide you how to install, test, use, operate and maintain the baler machine for free, which also include video support, email services, and in a word, we can get everything done.

> What is output capacity of Alu Cans Tins Recycling Baler?

The machine capacity ranges from 300kg per hour to 3000kg per hour, different models has differnt capacity, small models has small output capacity, and bigger one has big capacity accordingly.

> What all do I need to install the Light Steel Waste metal scrap Baler?

After the metal scrap baler machine arrived your place, you need the hydraulic oil, cable wire, worker, electrical technician, then you can start to test and operate the baler machine per user manual, or make video call with our engineer.

> What profits can we get from the Compressing A Scrap Metal Balers?

You need to know price of metal scrap, and price of the bales you sell to metal recycling center or steel manufacturer, then you can know how much profits you will get by this machine.

Hotline : +86 152 2134 7650

Hotline : +86 152 2134 7650 Email : info@diloya.com

Email : info@diloya.com

Product

Product Phone: +86 152 2134 7650

Phone: +86 152 2134 7650 E-mail: info@diloya.com

E-mail: info@diloya.com Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China

Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China