Scraping a compressor for recycling metals is a valuable and environmentally responsible practice. C...

| Basic Infomation | |

Incoterm: FOB,CFR,CIF,CIP | Oil Sealing: Hallite |

| Additional Information | |

Transportion: Ocean | Pipe Brand: High Pressure Pipe |

| Package And Delivery | |

Package: Wood package, Plastic Films, Nude Packing | Delivery: Ocean Shipping |

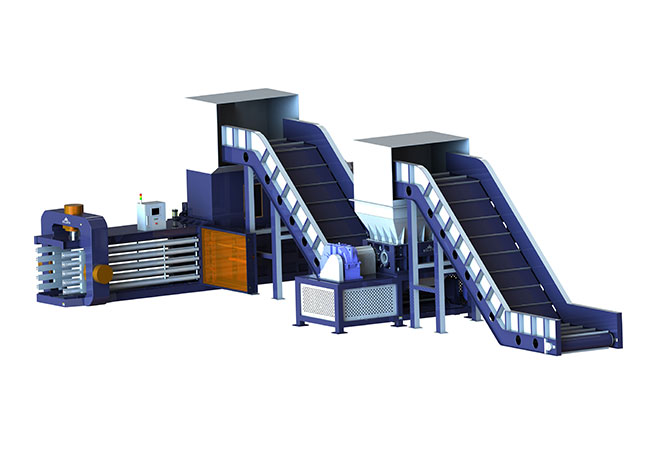

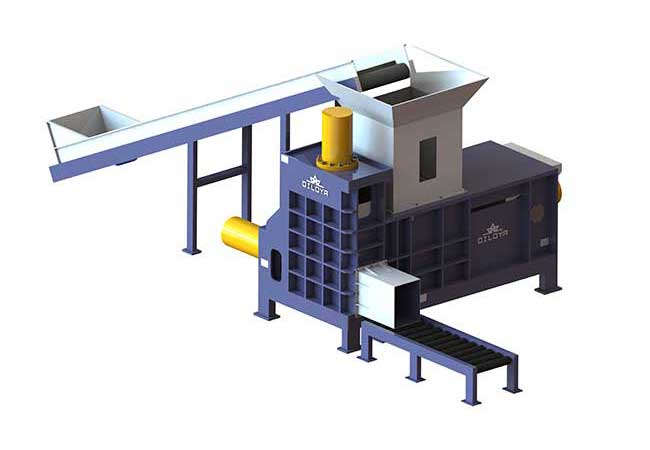

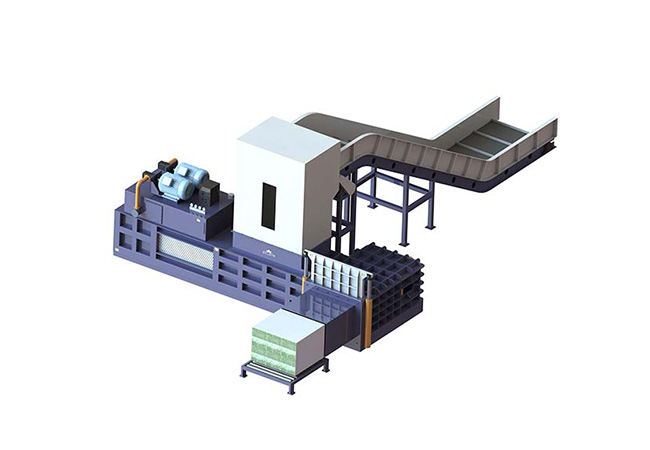

HBD Series Three Rams Bagging Press Baler Machine, mainly compress silage, hay straw, wheat straw, haylage, Alfalfa, chopped straw, corn silage, wood shavings, wood sawdust, corn cor granules, corncob flakes, etc...

The HBD Series Three Rams Bagging Press Baler Machine mainly used in agriculture industry, it is composed of three sections: hydraulic system, electrical system, main frame, can handle all kinds of silage such as silage, hay straw, wheat straw, haylage, Alfalfa, chopped straw, corn silage, etc..

Working Principle: The silage is put into the baler hopper by conveyor, then the side cylinder will press the silage to the limit several times which is set in our factory, then use a woven bag or plastic bags to hold the bale when the main cylinder pushing the bale out automatically, this way, the bale is finished completely, then start the next bale continuously.

An Automatic Silage Bagging Baler is a specialized piece of agricultural equipment used to compress and package silage (fermented fodder) into large, dense bales that can be wrapped in plastic film for storage. This type of baler automates the process of bagging silage, making it more efficient and reducing labor requirements on farms.

Key features and components typically include:

1. Baling chamber: Where the crop material is compressed into bales.

2. Automatic tying mechanism: For securing the bales with twine or net wrap.

3. Bagging system: A mechanism for placing a plastic bag over the bale as it's formed.

4. Wrapping arm: For wrapping the bagged bale with plastic film.

5. Control panel: For operator interface and settings adjustment.

6. Transport system: For moving the baled silage to storage areas.

7. Power source: Usually hydraulics or electricity, depending on the model.

Benefits of using an automatic silage bagging baler include:

- Increased efficiency in harvesting and storing silage

- Reduced labor requirements compared to manual bagging

- Improved silage quality through better compaction and sealing

- Easier handling and transport of stored silage

- Longer storage life due to better protection from air and moisture

These machines are particularly useful for large-scale farming operations where efficient silage production is critical. They allow farmers to optimize their crop management practices and improve overall farm productivity.

Parameter

Model | Bale Size (mm) | Bale Weight (Kg) | Power (Kw) |

HBD100 | 500X300X200 | 10-20 | 18.5 |

HBD150 | 600X300X300 | 15-30 | 22 |

HBD200 | 700X400X300 | 25-45 | 30 |

HBD250 | 750X430X310 | 35-50 | 37 |

If you have any special requirements, we will customize according to your special needs.

Product Show

|  |

|  |

|  |

|  |

|  |

|  |

Advantage

1. Adopts horizontal continuously push out type with Semi-auto bagging system.

2. Adopts latest design of three ram, bale density is more higher than two rams, more economical.

3. Fully automatic control, high efficiency, save labor cost, transportation cost, stock cost and space.

4. Bale size and bale weight can be customized according to your special requirement.

5. Output capacity varies from 2 to 5tons per hour, more options for your choices.

6. Bale weight can be up to 20-50kg per bale, and output bale quantity can be up to 100-120 bales per hour, more efficient.

7. Auto-inspecting system for silage to start or stop the machine automatically, save power energy, easy to operate and maintain.

8. Adopts German Hydraulic technology to promise the machine run smoothly, durable and reliable.

9. Adopts international brand of hydraulic pump and valves to prolong the service life of the baler machine.

Application

The baler machine can press below materials:

| |||

| Corn Cob Granules/Flakes | Cotton Seed Hulls | Corn/Grass Sialge | Rice Husks/Hulls |

|  |  |  |

| Wood Shavings | Alfalfa Hay Straw | Wheat Straw | Wood Sawdusts |

FAQ

> What is package of Corn silage baler india?

Generally speaking, there are two packages of the machine, wooden package, and plastic films, wooden package is mainly for small machine with LCL shipment, and plastic films mainly for big machine with FCL shipment.

> What are all the skills required to operate a Corn Silage Bagging Press manufactured by Diloya?

No special skills, just read the user manual carefully before operating the baler machine, if you have any questions, feel free to contact with us, we can help you at any time.

> How much price of China Supplier Corn Silage Bagging Baler?

Price of the baler machine is different, depends on how big of the machine is, but we can give you a word that our price of the machine is lower with high quality.

> How can i know you are a manufacturer or trader of Ce Silage Packing Machine?

You can visit our factory personally, also you can ask technical drawings such as 2D drawings 3D Drawings, we have professional technical team working on this, and will not give you these if a trader, because they don't have ability on this.

> How much would Silage and hay machinery in belarus , its installation, and training cost me?

The price of baler machine is different according to different bale size, bale weight and output capacity as for the installation, training cost, the machine is very easy, just put it on horizontal ground, adding hydraulic oil, connect to power supply, then operate per user manuals.

> How can we install the 30kg Haylage Square Baler Machine?

The baler machine is marked tips when shipping, and you can easily assemble the machine per the tips, after assembling, put it on the horizontal ground, adding hydraulic oil, connect to the power supply, then test and operate the machine per user manual, that is ok, if you have any questions, you can contact with us any time.

> Do you have a customer case of Chopped Straw Bagging Press Machine in our country for our reference?

We have many customers over the world, and one issue that we all signed the secret agreement with our customers, and then are not wiling to let other customers to visit their machines, as we all know, Peers are enemies.

> What is warranty time of the Hydraulic silage press baler?

The warranty time of the baler machine is 12 months normally, also can you can pay extra fees for more times such as 24 months or 36 months, within the warranty time, we are responsible for the baler machine except the spare parts.

Hotline : +86 152 2134 7650

Hotline : +86 152 2134 7650 Email : info@diloya.com

Email : info@diloya.com

Product

Product Phone: +86 152 2134 7650

Phone: +86 152 2134 7650 E-mail: info@diloya.com

E-mail: info@diloya.com Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China

Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China