Scraping a compressor for recycling metals is a valuable and environmentally responsible practice. C...

| Basic Infomation | |

Voltage: 3Phases; | PLC Brand: Siemens; |

| Additional Information | |

Training Service: Provided; | Lead Time: 15 Days; |

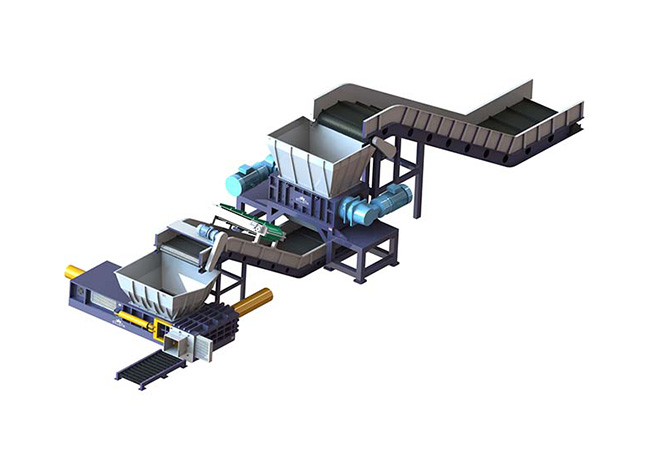

The Tin Can Compressing Machine is mainly compress the waste cans tins, ubc cans, stainless steel scrap, metal chips, mixed aluminum scrap into small bales with high density for steel manufacturer to remelt again, it is easy to transport, stock, can improve the rate of steel melting , it has other names such as China Pop-Top Cans Compactor,Low Price Aluminum Tins Baling Machine,Two Ram UBC Press Baler,Fast Aluminum Tins Compress Baler,Hydraulic Press For Waste Tin Compacting,Low Price Waste Cans Compactor Machine,100Ton Alu Cans Tins Baling Machine,Small UBC Packing Baler,Fast Aluminum Cans Compactor.

We not only have these baler machine, but have other machines such as China Supplier Tins Cans Baling Machine,Big Volume Hopper UBC Baling Machine,Low Price Stainless Steel Recycling Baler,125 Tons Pop-Top Cans Packing Baler,India Zip Top Cans Baling Machine,Small Waste Steel Compactor Machine,Y81T Used Metal Press Baler,250Ton Waste Steel Baling Machine,China Supplier Pop Cans Baling Machine,Steel scrap Baler Machine,100Ton Waste Steel Baling Machine,Heavy Duty Steel Scrap Compress Baler,High Speed UBC Packing Baler,Powerful Waste Bar Baling Press,Y81T Metal Scrap Compactor,Inida Metal Scrap Baler,Scrap Baling Press Machine In Low Price,India Ring-Pull Cans Baler,Big Volume Hopper Waste Cans Compactor,Low Price Tins Cans Baling Press,100 Tons Pop-Top Cans Compactor Machine,Powerful Iron Scrap Baling Machine,Fast Aluminum Tins Baling Machine,Hopper Feed Waste Cans Baler,China Supplier Light Metal Compactor,China Aluminum Scrap Compactor Machine,Heavy Duty Waste Steel Baling Machine,Fast Ring-Pull Cans Baling Machine,Remote Control Metal Scrap Compactor Machine,Hopper Feed Ring-Pull Cans Baler,Hopper Feed Copper Scrap Baler With Conveyor,Hydraulic System For Metal Baling Machine,Automatic Pop Cans Baling Press,Tin Can Compacting Machine,Big Volume Hopper UBC Baling Press,100Ton Used Beverage Cans Press Baler,100Ton UBC Baler,Powerful Waste Bar Compactor Machine,China Supplier Used Beverage Cans Baling Machine,Y81F Used Metal Compactor etc...

Please contact with us if you have any questions.

Video

Parameter

Model | CMS125 |

Bale Size | 300x300mm |

Bale Weight | 15-30kg |

Chamber Size | 1400x800x300mm |

Motor Power | 30kw |

Machine Weight | 7380kg |

If you have any special requirements, we will customize according to your special needs.

Product Show

|  |

|  |

|  |

|  |

Advantage

> Output capacity can be up to 30-60bales per hour, more efficient.

> Adopts simple structure, easy to operate and maintain.

> One Button automatic PLC Control, just need to push one button, you can operate the machine continuously.

> Remote Control is optional, can archive automatic operation without worker.

> Schneider electrical components prolong the service life of the machine.

> 24 hours reply, video, phone call, email support, if any question, we response at first time.

> Enough spare parts with lower cost to keep the machine non-stop.

> Lifelong after services let you have no any concern, get more porfits.

Application

The baler machine can press below materials:

|  |  |

| Aluminum cans tins | Light Metal Scrap | Copper Tube/Pipes |

|  |  |

| Aluminum Extrusion Profiles | Stainless Steel Scrap | Lead Strips |

|  |  |

| Copper Shavings | Aluminum Chips | Stainless Steel Chips |

FAQ

> How to operate How To Press Aluminium Tin?

This baler is very simple, just operate per user manual is ok, you can contact with us if you have any questions any time, we can guide you how to operate the baler machine.

> What is after-services of Aluminum Can Baler?

We provide training and installation services, we can guide you how to install, test, use, operate and maintain the baler machine for free, which also include video support, email services, and in a word, we can get everything done.

> How to maintain Tin Scrap Compacting Machine?

When you were operating the baler machine, you need to clean the oil tank every 3 months, and check the wire, and oil pipe leakage or not, and also check the bolt every shift, you can find all maintenance items in the user manual.

> What kind of wear steel plate does Non Ferrous Metal Scrap Recycling Baler use?

The baler machine use China famous brand wear steel NM450, the NM 45O wear steel plate is durable, stable, anti-wearable, no need to change the wear steel plate in lifetime of the baler machine, and further more, the World famous brand wear plate Hardox 450 is optional.

> What is wall thickness of Auto Aluminum Can Press Machine?

The wall thickness of the baler is different, big pressure force will use more thick wall thickness, and will use small thickness with small pressure force accordingly, for example, 100tons pressure force will use 12mm, and 315tons will use 25mm.

> What is lead time of Aluminium Metal Press Machine?

The lead time is various according to different models, generally speaking, it is approx. 30 days, and will be longer with bigger models, and shorter with small models, we will work overtime if you need the baler machine urgently.

> How much price of Tinplate Scrap Baling Press Baler?

Price of the baler machine is different, depends on how big of the machine is, but we can give you a word that our price of the machine is lower with high quality.

Hotline : +86 152 2134 7650

Hotline : +86 152 2134 7650 Email : info@diloya.com

Email : info@diloya.com

Product

Product Phone: +86 152 2134 7650

Phone: +86 152 2134 7650 E-mail: info@diloya.com

E-mail: info@diloya.com Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China

Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China