Scraping a compressor for recycling metals is a valuable and environmentally responsible practice. C...

| Basic Infomation | |

Cooling System: Water Cooling; | Feeding Method: Conveyor; |

| Additional Information | |

Baler Type: 2 Rams; | Training Service: Provided; |

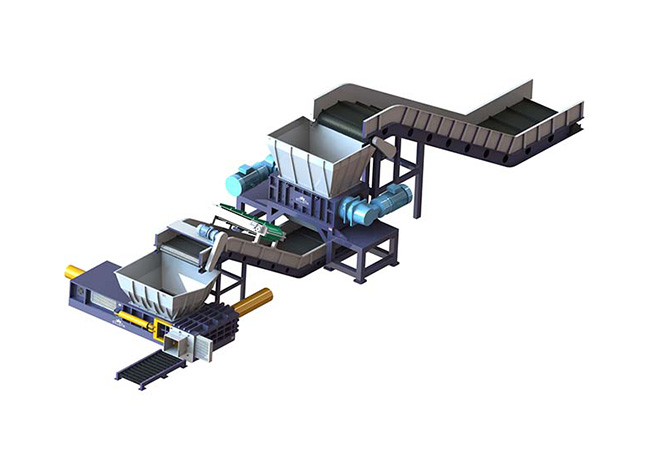

The Aluminum Cans Baler is mainly compress the metal chips, aluminum chips, brass chips, bronze shavings, aluminum shavings, metal scraps, aluminum scraps, stainless steel scrdaps into small bales with high density for metal manufacturer to remlelt again, easy to transport, stock and can highly improve the rate of melting, can make more profits, it has other names such as Stainless Steel Baling Press Machine,200 Ton Scrap metal press Baler,Scrap Metal 500 Tons Presser machine,Y81T Scrap Metal Baler ,Tcm Metal Baler,China Hydraulic Iron Scrap Press baler,Aluminium Mild Steel Scrap Baler Machine,Secondhand Tin Baler Machines In Pretoria,Baling Machine For Steel scrap.

We not only have these baler machine, but have other machines such as China Supplier Aluminum Tins Baler, Low Price Aluminum Extrusions Compactor Machine, India UBC Baler With Conveyor, Turn Out Steel Scrap Baling Press, 125Ton Tins Cans Baler, India Tins Cans Compactor, Automatic Tins Cans Compress Baler, Automatic Stainless Scrap Compactor Machine, Tin Scrap Pressing Machine, Y81T Steel Scrap Baling Press, 125 Tons Pop-Top Cans Baling Press, 100Ton Used Beverage Cans Compactor, Auto Feeding Scrap Hydraulic Press, China Stainless Scrap Baler With Conveyor, Automatic Aluminum Scrap Baling Press, Jiangsu Factory Iron Scrap Press Baler, Two Ram Zip Top Cans Baling Machine, Hopper Feed Stainless ScrapCompress Baler, Push Out Waste Steel Baling Machine, Big Volume Hopper Used Beverage Cans Baling Press, Two Ram Aluminum Tins Baling Press, Aluminium Tin Press Machine, Tin Baling Press Machine, Hopper Feed Pop Cans Press Baler, 160Ton Iron Scrap Baler, Pop Can Baler Machine, Hopper Feed Aluminum Tins Press Baler, Tin Scrap Compacting Machine, Inida Steel Scrap Baling Press, Fast Alu Cans Tins Baler, 125Ton Used Beverage Cans Press Baler, Automatic Stainless Steel Press Baler, 125 Tons Ring-Pull Cans Baler With Conveyor, Two Ram Copper Scrap Compress Baler, China Supplier Used Beverage Cans Compress Baler, Horizontal Baling Machine For Scrap Baling, 315Ton Steel Wire Compactor Machine, 100Ton Aluminum Cans Baler With Conveyor, Small Aluminum Cans Baler, Scrap Steel Baler Machine South Africa etc...

Please contact with us if you have any questions.

Video

Parameter

Model | CMS200 | CMS250 |

Bale Size | 400x400mm | 450x450mm |

Bale Weigh | 60-110kg | 120-180kg |

Chamber Size | 1800x1200x400mm | 2200x1400x450mm |

Motor Power | 30x2kw | 37x2kw |

Machine Weight | 16500kg | 19450kg |

If you have any special requirements, we will customize according to your special needs.

Product Show

|  |

|  |

|  |

|  |

Advantage

> Latest design of the machine to let you use the best the machine all the time.

> 24 hours reply, video, phone call, email support, if any question, we response at first time.

> Enough spare parts with lower cost to keep the machine non-stop.

> Can press varous of metal scraps, non metal scraps, stainless steel scrap, metal chips etc...

> Output capacity can be up to 30-60bales per hour, more efficient.

> World famous brand of Siemens PLC to promise you run the machine without any worry.

> Adopts simple structure, easy to operate and maintain.

Application

The baler machine can press below materials:

|  |  |  |

| Aluminum cans tins | Light Metal Scrap | Copper Tube/Pipes | Copper Turnnings |

|  |  |  |

| Aluminum Extrusion Profiles | Stainless Steel Scrap | Lead Strips | Aluminum Shavings |

FAQ

> Is there any spare parts along with the Tinplate Scrap Compression Baler Machine?

Yes, we will provideo some spare parts for free which inlucdes tools, O Rings and some other electrical components like middle relay, and you need to pay extra cost for wear parts.

> Do you have a customer case of Stainless Steel Scrap Hydraulic Press in our country for our reference?

We have many customers over the world, and one issue that we all signed the secret agreement with our customers, and then are not wiling to let other customers to visit their machines, as we all know, Peers are enemies.

> What profits can we get from the India Aluminum Cans Baling machine?

You need to know price of metal scrap, and price of the bales you sell to metal recycling center or steel manufacturer, then you can know how much profits you will get by this machine.

> Is your price of Compact Aluminum Scrap Baler machine competitive?

Yes, of course, our price is competitive, our price is cheaper than other suppliers such as tf baler, eco baler, wanshida baler, tcm baler, enerpat baler etc.. Because we are direct manufacturer of the baler machine, so we can promise the quality of the baler machine, and price is lower.

> Which country have you exported the Stainless Steel Compress Baler?

We have exported the baler machine to many countries such as Japan, Thailand, Malaysia, Singapore, Indonesia, India, Pakistan, Sri Lanka, Iraq, Iran , Qatar, Kuwait, Oman, Turkey, Finland, Sweden, Norway, Iceland, Denmark, Russia, Poland, Czech, Germany, Austria, Britain, Ireland, Netherlands, Belgium, France, Greece, Romania, Bulgaria, Albania, Slovenia, Croatia, Italy, Spain, Portugal, Egypt, Chile, Argentina, Ecuador, Canada, America, USA, Australia, New Zealand, South Africa, Mexico and other countries.

> Is it possbile to press other metal scraps with Aluminum Can Baler Unites States?

Yes, of course, this kind of shear baling machine can press various of metal scraps such as UBC, aluminum cans tins, aluminum chips, aluminum shaivngs, steel shavings, metal chips, light metal scraps and other non ferrous metal scrap etc... Please let us know what kind of metal scrap will you need to press, then we will suggest you suitable model baler machine and best offer accordingly.

> What is payment term of Tinplate Scrap Compressing Machine?

The payment of the baler machine is 30% TT as deposit, and 70%TT balance paid 7 days before shipment, and LC is also acceptable, it is flexible depends on amount of the baler machine.

Hotline : +86 152 2134 7650

Hotline : +86 152 2134 7650 Email : info@diloya.com

Email : info@diloya.com

Product

Product Phone: +86 152 2134 7650

Phone: +86 152 2134 7650 E-mail: info@diloya.com

E-mail: info@diloya.com Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China

Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China