A hydraulic press compresses metal scraps (like iron, aluminum, copper, etc.) into dense bales or bl...

| Basic Infomation | |

Port:Shanghai Port; | Bale Out Type:Continuous; |

| Additional Information | |

Incoterm:FOB,CFR,CIF,CIP; | Baler Type:3 Rams; |

| Package And Delivery | |

Package: Wood package, Plastic Films, Nude Packing | Delivery: Ocean Shipping |

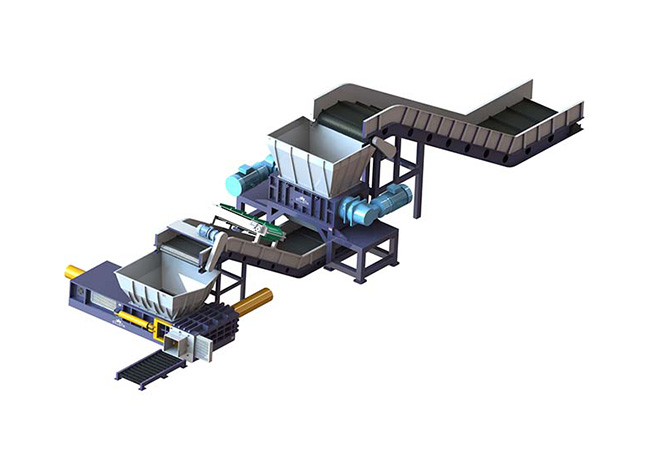

The Aluminum Can Baler Machine is mainly compress the metal chips, aluminum chips, brass chips, bronze shavings, aluminum shavings, waste cans tins, light metal scrap into small bales with high density for metal manufacturer to remlelt again, easy to transport, stock and can highly improve the rate of melting, can make more profits, it has other names such as Baler Baling Steel Rebar,Baling Aluminum Cans India,Auto Aluminum Can Press Machine,Scrap Baling Press Machine For Aluminum Profile,Stainless Sheet Metal Compressor Machine,Stainless Sheet Metal Baling Press,Non Ferrous Metal Baler,Stainless Steel Press Baling Machine,Metal Scrap Baler One Stop Automatically.

We not only have these baler machine, but have other machines such as Greece Automatic Vertical briquetting press for Copper shavings,Eco hydraulic Push Out Light Metal Baling Machine,Aupu machinery baler Y81Q Steel Scrap Baler,Sweden India Copper Scrap Compress Baler,Australia China steel Shavings briquette machine,Turkey 100 Tons Pop-Top Cans Packing Baler,Sri Lanka Best Performance Copper chips block making machine,Ireland Scrap Rebar Shear,Shengbo baler Low Price Copper Scrap Recycling Baler,Slovenia High density briqeutting press for Aluminum borings,Indonesia Automatic Aluminum Drillings briquette machine,Chuangda baler Low cost Copper Shavings baler,Romania Turn Out Scrap Metal Baling Press,Finland Y83 aluminum Swarfs briquetting machine,Portugal Cutting Shears Used For Sheet Metal Shears,Chile China Supplier Metal Scrap Baler,Enerpat baler Metal Chip Briquetting Press Machine,Singapore High Quality Brass Drillings briquetter,Netherlands Automatic Stainless Scrap Compactor Machine,Mexico 250Ton Steel Wire Alligator Shear,Japan Automatic Stainless Steel Drillings baler,SK BalerBest Performance Bronze borings block making machine,South Africa Hydraulic block making machine for Aluminum shavings,France Metal Chip Briquetting System,Malaysia Nice Ce Certificated Metal Briquetting Presses,Dongfang hydraulic Vertical Stainless Steel Millings baling machine,Albania Y83 cast iron Powder briquetting machine,Bulgaria High Quality Brass Drillings baler,Kuwait 200Ton Steel Plate Cutter Machine,Thailand Automatic Vertical Briquetting machine for Copper millings,Huahong baler Hydraulic Iron Scrap Press Machine,Oman Small Tins Cans Baling Press,USA Automatic briquetting machine for Metal turnings,Tianfu baler Y83 steel Turnings briquetter,Canada Low Price Alu Cans Tins Baler,Jiangyin manufacturer Automatic Metal turnings block making machine,Iran 250Ton Metal Scrap Compactor,Poland High density Brass Chips briquetter,Jiangyin supplier Hydraulic Steel Plate Cutter Machine,New Zealand Low Price Ring-Pull Cans Baler With Conveyor etc...

Please contact with us if you have any questions.

Parameter

Model | Box Size (mm) | Bale Size (mm) | Bale Weight (Kg) | Power (Kw) |

CM100 | 100X600X500 | 200X200 | 20-40 | 11 |

CM125 | 1200X700X600 | 300X300 | 30-50 | 15 |

CM135 | 1400X900X800 | 350X350 | 60-100 | 18.5 |

CM160 | 1600X1200X800 | 400X400 | 80-120 | 22 |

CM200 | 2000X1400X900 | 450X450 | 150-250 | 37 |

CM250 | 2200X1400X1000 | 500X500 | 200-300 | 2x30 |

If you have any special requirements, we will customize according to your special needs.

Product Show

|  |

|  |

|  |

|  |

Advantage

> Enough spare parts with lower cost to keep the machine non-stop.

> Schneider electrical components prolong the service life of the machine.

> Can press varous of metal scraps, non metal scraps, stainless steel scrap, metal chips etc...

> Stable hydraulic system to keep the machine run well.

> Output capacity can be up to 20-30bales per hour, more efficient.

> Lifelong after services let you have no any concern, get more porfits.

> Adopts china famous pump to keep baler machine run smoothly.

> Adopts simple structure, easy to operate and maintain.

Application

The baler machine can press below materials:

|  |  |

| Aluminum cans tins | Light Metal Scrap | Coppe Wire Scrap |

|  |  |

| Aluminum Extrusion Profiles | Stainless Steel Scrap | Aluminum Shavings |

|  |  |

|  |  |

FAQ

> Does the installation of Cheapest Aluminium Scrap Compress Machine require drilling and bolting into the floor or can stand without drilling?

Regarding the drillings or not, it depends on the type of baler machine, for vertical baler machine, most of vertical baling machine needs drilling and bolting, because it is vertical type, and weight center of the machine is high; and for horizontal baler, it no need foundation, drilling and bolting, just put it on horizontal cement gound wich thickness more than 150mm.

> What is the weight of Tcm Cans Tins Baling Machine?

The weight of the machine is different, different type of baler machine is differetn, for small vertical baler machine, the weight is small, and for metal scrap baler machine, the weight is heavy and big.

> What is warranty time of the Iron Scrap steel metal Press Machine? The warranty time of the baler machine is 12 months normally, also can you can pay extra fees for more times such as 24 months or 36 months, within the warranty time, we are responsible for the baler machine except the spare parts.

> What is lead time of Iron steel Scrap Baling machine?

The lead time is various according to different models, generally speaking, it is approx. 30 days, and will be longer with bigger models, and shorter with small models, we will work overtime if you need the baler machine urgently.

> Does Steel Press Machine Recycle have PLC control?

Yes, the machine has PLC automatic control, easy to operate and more efficient, and also has manual control, easy to debug and maintain the baler machine.

> What profits can we get from the Light metal Scrap Press Machine?

You need to know price of metal scrap, and price of the bales you sell to metal recycling center or steel manufacturer, then you can know how much profits you will get by this machine.

> Which country have you exported the Fully Automatic Pressing Machine For Scrap metal?

We have exported the baler machine to many countries such as Japan, Thailand, Malaysia, Singapore, Indonesia, India, Pakistan, Sri Lanka, Iraq, Iran , Qatar, Kuwait, Oman, Turkey, Finland, Sweden, Norway, Iceland, Denmark, Russia, Poland, Czech, Germany, Austria, Britain, Ireland, Netherlands, Belgium, France, Greece, Romania, Bulgaria, Albania, Slovenia, Croatia, Italy, Spain, Portugal, Egypt, Chile, Argentina, Ecuador, Canada, America, USA, Australia, New Zealand, South Africa, Mexico and other countries.

Hotline : +86 152 2134 7650

Hotline : +86 152 2134 7650 Email : info@diloya.com

Email : info@diloya.com

Product

Product Phone: +86 152 2134 7650

Phone: +86 152 2134 7650 E-mail: info@diloya.com

E-mail: info@diloya.com Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China

Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China