A hydraulic press compresses metal scraps (like iron, aluminum, copper, etc.) into dense bales or bl...

| Basic Infomation | |

Monthly Throughput:30-600tons; | Bale Size:300-600mm; |

| Additional Information | |

Debugging Service:Provided; | Machine Productivity:0.5-5tons/Hour; |

| Package And Delivery | |

Package: Wood package, Plastic Films, Nude Packing | Delivery: Ocean Shipping |

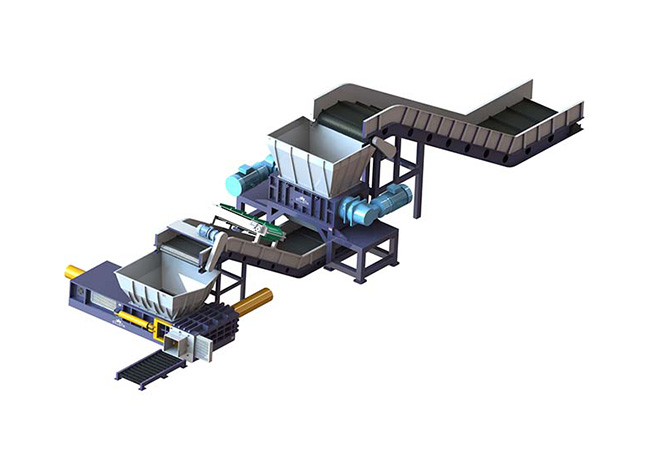

The Scrap steel rebar Wire Baler China is mainly compress the metal chips, aluminum chips, brass chips, bronze shavings, aluminum shavings, waste cans tins, light metal scrap into small bales with high density for metal manufacturer to remlelt again, easy to transport, stock and can highly improve the rate of melting, can make more profits, it has other names such as Push Out Metal Scrap Baler,200Ton Steel Scrap Compress Baler,Compressing Steel Scrap baler machine,Heavy Duty Metal Baler machine,Metal Baler Cans,Tcm Baler Heavy Duty Scrap press machine,Non Ferrous Metal Scrap Baler Machine,Heavy Metal Scrap Baling Machine,Metal Scrap Baling Machine In India.

A scrap metal compactor baling machine, also known as a metal baler or metal compactor, is a piece of industrial equipment used to compress and form scrap metal into compact, manageable bales. These machines are widely used in recycling facilities, scrapyards, and manufacturing plants to efficiently handle and transport scrap metal.

Here’s an overview of what you need to know about these machines:

Key Features and Components

1. Hydraulic System: The primary mechanism for compressing the metal. It uses hydraulic cylinders to apply high pressure to the scrap, forcing it into a dense, compact shape.

2. Feeding Mechanism: This can be manual or automated, depending on the model. It allows the scrap metal to be fed into the compression chamber.

3. Compression Chamber: The area where the scrap metal is compressed. It is designed to withstand high pressures and is often made from durable materials like steel.

4. Bale Ejection System: Once the bale is formed, this system helps to eject it from the machine. Some models may have automatic ejection, while others require manual intervention.

5. Control Panel: Used to operate the machine, including starting, stopping, and adjusting the compression settings. Modern machines often feature touch-screen interfaces and programmable controls.

Types of Scrap Metal Compactors

1. Horizontal Balers: These machines compress scrap metal horizontally, producing bales that are typically easier to handle and stack.

2. Vertical Balers: Compress scrap metal vertically. They are often more compact and suitable for smaller operations.

3. Specialized Balers: Designed for specific types of scrap metal, such as non-ferrous metals (aluminum, copper) or ferrous metals (iron, steel).

Benefits of Using a Scrap Metal Compactor Baling Machine

1. Space Efficiency: Reduces the volume of scrap metal, making it easier to store and transport.

2. Cost Savings: Reduces transportation costs by minimizing the number of trips needed to haul scrap metal.

3. Environmental Impact: Promotes recycling by making it more efficient and cost-effective to process and reuse scrap metal.

4. Safety: Reduces the risk of injury associated with handling loose scrap metal by creating stable, uniform bales.

Considerations When Choosing a Scrap Metal Compactor Baling Machine

1. Capacity and Throughput: Determine the amount of scrap metal you need to process and choose a machine with the appropriate capacity.

2. Type of Scrap Metal: Different machines are better suited for different types of metal. Ensure the machine can handle the specific types of scrap you deal with.

3. Automation Level: Decide whether you need a fully automated, semi-automated, or manual machine based on your operational needs and budget.

4. Maintenance and Support: Consider the availability of spare parts, maintenance services, and technical support from the manufacturer.

Safety Precautions

1. Training: Ensure that operators are properly trained to use the machine safely.

2. Personal Protective Equipment (PPE): Operators should wear appropriate PPE, including gloves, safety glasses, and hard hats.

3. Regular Maintenance: Regularly inspect and maintain the machine to ensure it operates safely and efficiently.

4. Emergency Stops: Ensure that the machine has easily accessible emergency stop buttons and that operators know how to use them.

By understanding the features, benefits, and considerations of a scrap metal compactor baling machine, you can make an informed decision when selecting one for your operation.

Parameter

Model | CM125 | CM135 | CM160 | CM200 | CM250 | CM315 |

Chamber Size(mm) | 1200x700x600 | 1400x900x800 | 1600x1200x800 | 1800x1400x900 | 2000x1400x1000 | 2500x2000x1200 |

Bale Size(mm) | 300x300mm | 350x350mm | 400x400mm | 450x450mm | 500x500mm | 600x600mm |

Bale Weight(kg) | 40-70kg | 60-100kg | 80-150kg | 130-200kg | 200-300kg | 250-400kg |

Power(mm) | 15kw | 18.5kw | 22kw | 30kw | 2x22kw | 2x37kw |

Machine Weight(kg) | 6250kg | 7380kg | 11540kg | 19840kg | 24580kg | 28420kg |

Machine Size(mm) | 4250x2180x1980 | 4380x2390x2120 | 4780x2560x2150 | 5140x2920x2360 | 5280x2990x2650 | 7380x3850x3260 |

If you have any special requirements, we will customize according to your special needs.

Product Show

|  |

|  |

|  |

|  |

Advantage

> Schneider electrical components prolong the service life of the machine.

> 24 hours reply, video, phone call, email support, if any question, we response at first time.

> World famous brand of Siemens PLC to promise you run the machine without any worry.

> Stable hydraulic system to keep the machine run well.

> Strong structure of the machine, reliable, stable and durable, let you make more money.

> Enough spare parts with lower cost to keep the machine non-stop.

> Long warranty time of the baler machine, you are no need to worry about the after-services.

> Remote Control is optional, can archive automatic operation without worker.

Application

The baler machine can press below materials:

|  |  |  |

| Aluminum cans tins | Light Metal Scrap | Copper Tube/Pipes | Coppe Wire Scrap |

|  |  |  |

| Aluminum Extrusion Profiles | Stainless Steel Scrap | Lead Strips | Aluminum Shavings |

FAQ

> Is it possible to change the wear plate on Tin Can Compression Baler Machine?

We have two method to fix the wear steel plate, one is welding the wear plate on the baler machine, and another type is changeable, whichever type of fixing, we can do it per your special requirement.

> What is HS Code of Non Ferrous Metal Scrap Balers?

Generally speaking, we use HS Code 8422400090 for the baler machine, and we can use other HS Code per your convinience.

> How much is the shipping cost of Aluminium Can Recycling Baler Equipment ?

The shipping cost is varying over time,and different models of baler machine will need different containers to hold, if peak season and bigger models, the shipping cost will be higher, and on the contrary, the cost will be lower.

> What is the weight of Machine Press Aluminium Cans?

The weight of the machine is different, different type of baler machine is differetn, for small vertical baler machine, the weight is small, and for metal scrap baler machine, the weight is heavy and big.

> Do you have a agent of Waste Aluminium And Tin Can Pressing Machine in our country?

No, we don't have agent or representative in your country, we directly export the machine to our end users, this way, the price will be lower, and end users can get more money.

> What is voltage of Scrap Metal Bundle Press Machine?

For the voltage of the machine, no need to worry about that, we will customize the motor per your local voltage and frequency, and the important thing that the baler machine must need 3 phases electrical power supply.

> Are you a manufacturer or a trader of 200Ton Steel Scrap Compress Baler?

We are true manufacturer of scrap metal baler machine, we have our own technical team, R&D team, have many processing machines, and you are warmly welcome to visit our factory personally.

Hotline : +86 152 2134 7650

Hotline : +86 152 2134 7650 Email : info@diloya.com

Email : info@diloya.com

Product

Product Phone: +86 152 2134 7650

Phone: +86 152 2134 7650 E-mail: info@diloya.com

E-mail: info@diloya.com Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China

Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China