A hydraulic press compresses metal scraps (like iron, aluminum, copper, etc.) into dense bales or bl...

| Basic Infomation | |

Pump Brand: JiangSu Hengyuan; | Output Capacity: 40-90bales/Hour; |

| Additional Information | |

None-Load Cycle: 60s; | Training Service: Provided; |

| Package And Delivery | |

Package: Wood package, Plastic Films, Nude Packing | Delivery: Ocean Shipping |

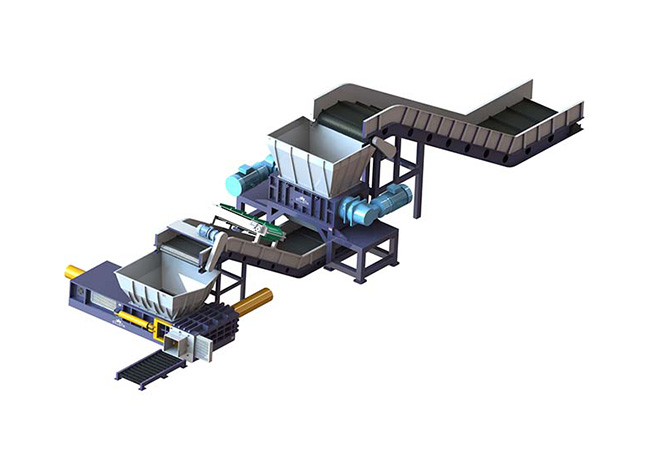

The Russian Compact Scrap metal Baler is mainly compress the waste cans tins, ubc cans, stainless steel scrap, metal chips, mixed aluminum scrap into small bales with high density for steel manufacturer to remelt again, it is easy to transport, stock, can improve the rate of steel melting , it has other names such as Tin Can Baling Press Baler,Tin Scrap Baler Machine,Stainless Sheet Metal Baler Press Machine,Hot To Compres Used Cans,Non Ferrous Metal Scrap Baler Machine,Metal Recycling Equipment Baling machine,Aluminum Tin Scrap Compression,Auto Scrap metal Compactor,Stainless Steel Packaging Machine.

An Aluminum/Tin Can Baler is a piece of equipment used to compress and bundle aluminum and tin cans for easier handling, transportation, and recycling.

Here are some key points about aluminum/tin can balers:

1. Purpose: | 2. Types: | 3. Capacity: |

4. Key components: | 5. Materials: | 6. Features: |

7. Benefits: | 8. Applications: | 9. Maintenance: |

10. Safety considerations:

- Proper training required

- Use of personal protective equipment

- Adherence to manufacturer's safety guidelines

When selecting an aluminum/tin can baler, consider factors such as daily processing needs, available space, budget, and desired level of automation, Please contact with us if you have any questions.

Video

Parameter

Model | Box Size (mm) | Bale Size (mm) | Bale Weight (Kg) | Power (Kw) |

CMS160 | 1500X1000X350 | 350X350 | 70-120 | 30x2 |

CMS200 | 1800X1400X400 | 400X400 | 120-180 | 37x2 |

CMS315 | 2000X1400X500 | 500X500 | 120-250 | 37X3 |

If you have any special requirements, we will customize according to your special needs.

Product Show

|  |  |  |

|  |  |  |

|  |  |  |

Advantage

> Stable hydraulic system to keep the machine run well.

> Can press varous of metal scraps, non metal scraps, stainless steel scrap, metal chips etc...

> Enough spare parts with lower cost to keep the machine non-stop.

> Cycle time can be upto 30 seconds, and 120bales per hour, more efficiently, can help you save lots of money.

> 24 hours reply, video, phone call, email support, if any question, we response at first time.

> One Button automatic PLC Control, just need to push one button, you can operate the machine continuously.

> The bale weight ranges from 20kg to 300kg, more options for your choices.

> World famous brand of Siemens PLC to promise you run the machine without any worry.

Application

The baler machine can press below materials:

|  |  |  |

| Aluminum cans tins | Light Metal Scrap | Copper Tube/Pipes | Copper Turnnings |

|  |  |  |

| Bronze Chips | Brass Chips | Steel Turnings | Aluminum Turnings |

|  |  |  |

FAQ

> How do I decide the model of Type Of Scrap Hydraulic Press Bundle that I need?

First, you need to know what bale size and bale weight are popular in your local market, then you produce the bale weight and bale size, and we can suggest you suitable model of wiper baler machine accordingly, Before this, you need to make investigation in your market, you can inquire your end user etc..

> How to maintain Metal Scrap Press Bundle Machine?

When you were operating the baler machine, you need to clean the oil tank every 3 months, and check the wire, and oil pipe leakage or not, and also check the bolt every shift, you can find all maintenance items in the user manual.

> What bale weight can the Automatic Aluminum Can Baler make?

Normally speaking, the bale weight rangs from 20kg to 300kg, it varys according to your metal scrap and your requirement, we have standard bale size and bale weight, can send you the catalogue for your reference.

> Which country have you exported the Ferrous Metal Baler machine?

We have exported the baler machine to many countries such as Japan, Thailand, Malaysia, Singapore, Indonesia, India, Pakistan, Sri Lanka, Iraq, Iran , Qatar, Kuwait, Oman, Turkey, Finland, Sweden, Norway, Iceland, Denmark, Russia, Poland, Czech, Germany, Austria, Britain, Ireland, Netherlands, Belgium, France, Greece, Romania, Bulgaria, Albania, Slovenia, Croatia, Italy, Spain, Portugal, Egypt, Chile, Argentina, Ecuador, Canada, America, USA, Australia, New Zealand, South Africa, Mexico and other countries.

> How long of warranty time of Tin Can Compacting Machine?

The warranty time is 14 months, in another word, 1 year from date of shiping the machine.

> How much is the shipping cost of China Steel Scrap metal Press Machine?

The shipping cost is varying over time,and different models of baler machine will need different containers to hold, if peak season and bigger models, the shipping cost will be higher, and on the contrary, the cost will be lower.

> What are the service requirements of the Scrap Pressing Indian Machine?

No need special requirements, just contact with our technical team, that is ok, we can get everything done.

Hotline : +86 152 2134 7650

Hotline : +86 152 2134 7650 Email : info@diloya.com

Email : info@diloya.com

Product

Product Phone: +86 152 2134 7650

Phone: +86 152 2134 7650 E-mail: info@diloya.com

E-mail: info@diloya.com Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China

Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China