A hydraulic press compresses metal scraps (like iron, aluminum, copper, etc.) into dense bales or bl...

| Basic Infomation | |

Driven Type: Hydraulic Driven; | Productivity: 30-50sets/Month; |

| Additional Information | |

Brand: Diloya; | Wear Plate: NM450 or Hardox450; |

| Package And Delivery | |

Package: Wood package, Plastic Films, Nude Packing | Delivery: Ocean Shipping |

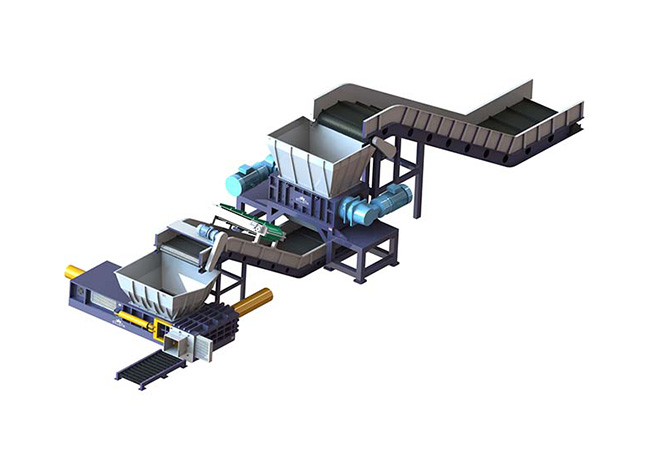

The Hydraulic Briquetting Press Machine For Copper is mainly compress the metal chips, aluminum chips, brass chips, bronze shavings, aluminum shavings into small bales with high density for metal manufacturer to remlelt again, easy to transport, stock and can highly improve the rate of melting, can make more profits, it has other names such as Brass Powder Briquetting Press 360 Ton,Bronze drillings briquette machine,Recycle Chips Aluminum Briquette Machine,Bronze Powder block making machine,Metal Chip Briquetting Machine,New Customized Waste Metal Chip Briquetting,Briquetting Press For Bronze Chips,Metal Chip Briquetting Presses From China,Sawdust Iron Steel Cutting Powder Briquetting Machine.

A Copper Turnings Briquetting Machine is a specialized piece of equipment used for compressing copper turnings (small pieces or scraps of copper) into compact blocks or briquettes.

This process can be beneficial for several reasons:

1. Space Efficiency: Compressing copper turnings into dense briquettes reduces the volume significantly, making storage and transportation more efficient.

2. Value Preservation: By preventing oxidation and contamination, briquetting helps maintain the quality and value of the copper material.

3. Recycling and Reuse: The compact form makes it easier to handle and process the material for recycling or reuse in various industries.

The machine typically consists of components such as:

-Feeding System: To feed the copper turnings into the machine.

-Compression Mechanism: This could be hydraulic or mechanical, which applies pressure to compress the material.

-Ejection System: To remove the formed briquette from the machine once it's compressed.

-Control System: For adjusting parameters like pressure and speed, and monitoring the operation.

When choosing or using a Copper Turnings Briquetting Machine, consider factors like the capacity needed, the quality of briquettes required, and the specific type of copper turnings being processed. Additionally, safety features and maintenance requirements should also be taken into account.

Parameter

Model | Bale Size (mm) | Bale Weight (Kg) | Power (Kw) |

BP250 | Φ100X(50-80) | 2.3-3.2 | 22 |

BP315 | Φ120X(60-100) | 4.2-5.5 | 30 |

BP360 | Φ120X(60-100) | 4.8-6.5 | 30 |

BP400 | Φ130X(70-100) | 6.2-8.1 | 37 |

BP500 | Φ140X(80-120) | 7.6-9.4 | 2x22 |

BP630 | Φ160X(90-120) | 8.5-10.5 | 2x30 |

BP800 | Φ200X(100-160) | 13.5-18.6 | 2x45 |

If you have any special requirements, we will customize according to your special needs.

Product Show

|  |

|  |

|  |

|  |

|  |

Advantage

> Adopts high speed structure to reduce cycle time for every one bale.

> Adopts pre-press structure to keep high output capacity with high density.

> Schneider electrical components prolong the service life of the machine.

> Strong structure of the machine, reliable, stable and durable, let you make more money.

> Enough spare parts with lower cost to keep the machine non-stop.

> Long warranty time of the baler machine, you are no need to worry about the after-services.

> Latest design of the machine to let you use the best the machine all the time.

> The bale weight ranges from 1.5kg to 22kg, more options for your choices.

Application

The baler machine can press below materials:

|  |  |  |

| Copper Rice Granules | Bronze Chips | Brass Chips | Copper Shavings |

|  |  | |

| Iron Cast Chips | Aluminu Shavings | Metal Chips | Stainless Steel Chips |

|  |  |  |

| Copper Cloves | Copper Chips | ||

|  |  |  |

FAQ

> What is package of Metal Shaving Compactor?

Generally speaking, there are two packages of the machine, wooden package, and plastic films, wooden package is mainly for small machine with LCL shipment, and plastic films mainly for big machine with FCL shipment.

> How to choose your Hydraulic Scrap Metal Aluminum Briquetting Press correctly?

As for this issues, first, you need to know which model of the briquetting press machine will you need, then you can compare price, quality, services of the machine from different suppliers, and at last you will know which supplier is better.

> What is payment term of Metal Chip Briquetter Machine?

The payment of the briquetting press machine is 30% TT as deposit, and 70%TT balance paid 7 days before shipment, and LC is also acceptable, it is flexible depends on amount of the machine.

> Which country have you exported the Brass Chips briquetter?

We have exported the bbriquetting press machine to many countries such as Japan, Thailand, Malaysia, Singapore, Indonesia, India, Pakistan, Sri Lanka, Iraq, Iran , Qatar, Kuwait, Oman, Turkey, Finland, Sweden, Norway, Iceland, Denmark, Russia, Poland, Czech, Germany, Austria, Britain, Ireland, Netherlands, Belgium, France, Greece, Romania, Bulgaria, Albania, Slovenia, Croatia, Italy, Spain, Portugal, Egypt, Chile, Argentina, Ecuador, Canada, America, USA, Australia, New Zealand, South Africa, Mexico and other countries.

> What is Metal Chip Ball Press Machine?

The machine is mainly used to compress steel chips, aluminum chips, brass chips, stainless steel chips bronze shavings, copper shavings, etc into small bales with high density, easy to transport and stock, save transport cost, stack cost, convenient for metal manufacturer to meal again, improve the product rate.

> Is your price of Bronze turnings baler competitive?

Yes, of course, our price is competitive, our price is cheaper than other suppliers such as eco baler,Wanshida baler, TF Baler, Gaode Baler, tcm baler, enerpat baler etc.. Because we are direct manufacturer of the baler machine, so we can promise the quality of the baler machine, and price is lower.

> Are you a manufacturer or a trader of Bronze Powder briquetter?

We are true manufacturer of briquetting press machine, we have our own technical team, R&D team, have many processing machines, and you are warmly welcome to visit our factory personally.

Hotline : +86 152 2134 7650

Hotline : +86 152 2134 7650 Email : info@diloya.com

Email : info@diloya.com

Product

Product Phone: +86 152 2134 7650

Phone: +86 152 2134 7650 E-mail: info@diloya.com

E-mail: info@diloya.com Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China

Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China