A hydraulic press compresses metal scraps (like iron, aluminum, copper, etc.) into dense bales or bl...

| Basic Infomation | |

Monthly Throughput: 500-3000tons; | Discharge Out: Automatic Continuous Out; |

| Additional Information | |

Payment Term: T/T L/C; | Bale Size: Dia 60-240mm; |

| Package And Delivery | |

Package: Wood package, Plastic Films, Nude Packing | Delivery: Ocean Shipping |

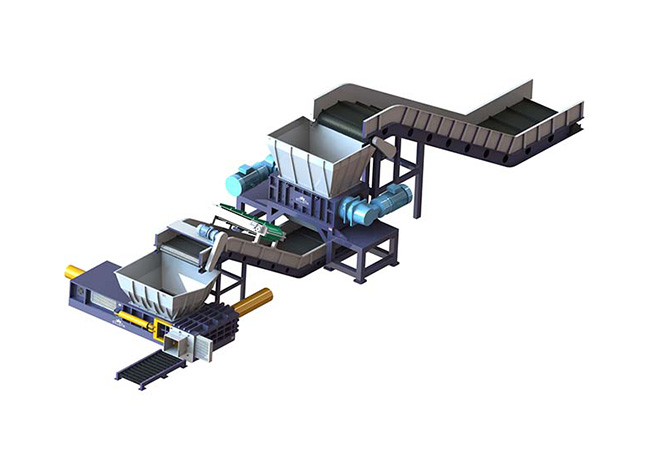

The Bronze Swarfs baling machine is mainly compress the metal chips, aluminum chips, brass chips, bronze shavings, aluminum shavings into small bales with high density for metal manufacturer to remlelt again, easy to transport, stock and can highly improve the rate of melting, can make more profits, it has other names such as Hydraulic Aluminum Press Briquetting Machine,Hydraulic Metal Chips Briquetting Press,Metal Chips Press Machine,Best Performance Brass Briquetting Press Machine,Iron Chips Briquette Pressing,Metal Chip Compactor,Brass Chips briquetter,Ruf Swarf Briquetting Press,Hydraulically Operated Chips Compactor Machines.

A Brass Powder Briquetting Press Machine is used to compress brass powder or other metal powders into solid shapes, typically for the purpose of recycling or creating raw materials for further processing. This type of machinery is common in industries where metal recycling and processing are essential, such as the metalworking, foundry, and recycling industries.

Key aspects of a Brass Powder Briquetting Press Machine include:

1. Functionality: It compacts loose metal powders like brass into dense briquettes, which can be easier to handle, transport, and process.

2. Design: The machine typically consists of a feeding system, a hydraulic press mechanism, and a control panel. The hydraulic press applies high pressure to compress the material.

3. Pressure Levels: High-pressure application is crucial for ensuring that the briquettes are compact and dense enough for efficient use or recycling.

4. Output Shape: Depending on the dies used, the machine can produce briquettes in various shapes, sizes, and densities.

5. Automation: Many modern machines offer varying degrees of automation, from simple manual operation to fully automated systems with programmable controls.

6. Environmental Impact: By reducing the volume of metal waste, these machines help reduce the space required for storage and the environmental impact associated with waste disposal.

7. Energy Efficiency: Efficient operation is important to minimize energy consumption while achieving the desired compression results.

If you have specific questions about how this machine works, its applications, or any other details, feel free to ask!

Please contact with us if you have any questions.

Parameter

Model | Bale Size (mm) | Bale Weight (Kg) | Power (Kw) |

BP360 | Φ120X(60-100) | 4.8-6.5 | 30 |

BP400 | Φ130X(70-100) | 6.2-8.1 | 37 |

BP500 | Φ140X(80-120) | 7.6-9.4 | 2x22 |

BP630 | Φ160X(90-120) | 8.5-10.5 | 2x30 |

BP800 | Φ200X(100-160) | 13.5-18.6 | 2x45 |

If you have any special requirements, we will customize according to your special needs.

Product Show

|  |

|  |

|  |

|  |

Advantage

> Latest design of the machine to let you use the best the machine all the time.

> Long warranty time of the baler machine, you are no need to worry about the after-services.

> Adopts pre-press structure to keep high output capacity with high density.

> Schneider electrical components prolong the service life of the machine.

> Adopts high speed structure to reduce cycle time for every one bale.

> Stable hydraulic system to keep the machine run well.

> Adopts china famous pump to keep baler machine run smoothly.

> One Button automatic PLC Control, just need to push one button, you can operate the machine continuously.

Application

The baler machine can press below materials:

|  |  |  |

| Copper Rice Granules | Bronze Chips | Brass Chips | Copper Shavings |

|  |  | |

| Iron Cast Chips | Aluminu Shavings | Metal Chips | Stainless Steel Chips |

|  |  |  |

| Copper Cloves | Copper Chips | ||

|  |  |  |

FAQ

> Which country have you exported the Aluminium Turning Scrap Baling Machine?

We have exported the bbriquetting press machine to many countries such as Japan, Thailand, Malaysia, Singapore, Indonesia, India, Pakistan, Sri Lanka, Iraq, Iran , Qatar, Kuwait, Oman, Turkey, Finland, Sweden, Norway, Iceland, Denmark, Russia, Poland, Czech, Germany, Austria, Britain, Ireland, Netherlands, Belgium, France, Greece, Romania, Bulgaria, Albania, Slovenia, Croatia, Italy, Spain, Portugal, Egypt, Chile, Argentina, Ecuador, Canada, America, USA, Australia, New Zealand, South Africa, Mexico and other countries.

> Do you have a customer case of Brass Powder Briduetting Press machine in our country for our reference?

We have many customers over the world, and one issue that we all signed the secret agreement with our customers, and then are not wiling to let other customers to visit their machines, as we all know, Peers are enemies.

> What is payment term of Iron Brass Briquetting Machine?

The payment of the briquetting press machine is 30% TT as deposit, and 70%TT balance paid 7 days before shipment, and LC is also acceptable, it is flexible depends on amount of the machine.

> How to maintain Hydraulic Aluminum Press Briquetting Machine?

When you were operating the machine, you need to clean the oil tank every 3 months, and check the wire, and oil pipe leakage or not, and also check the bolt every shift, you can find all maintenance items in the user manual.

> How can i know you are a manufacturer or trader of Stainless Steel Swarf Briquette Press?

You can visit our factory personally, also you can ask technical drawings such as 2D drawings 3D Drawings, we have professional technical team working on this, and will not give you these if a trader, because they don't have ability on this.

> Do you have a agent of Automatic Metal Chips Baler in our country?

No, we don't have agent or representative in your country, we directly export the machine to our end users, this way, the price will be lower, and end users can get more money.

> What are all the skills required to operate a Bronze millings baling machine manufactured by Diloya?

No special skills, just read the user manual carefully before operating the briquetting press machine, if you have any questions, feel free to contact with us, we can help you at any time.

Hotline : +86 152 2134 7650

Hotline : +86 152 2134 7650 Email : info@diloya.com

Email : info@diloya.com

Product

Product Phone: +86 152 2134 7650

Phone: +86 152 2134 7650 E-mail: info@diloya.com

E-mail: info@diloya.com Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China

Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China