A hydraulic press compresses metal scraps (like iron, aluminum, copper, etc.) into dense bales or bl...

| Basic Infomation | |

Hydraulic Force: 30-150tons; | Electric Power: 5.5-2x22kw; |

| Additional Information | |

Transportion: Ocean Shipping; | Lead Time: 15 Days; |

| Package And Delivery | |

Package: Wood package, Plastic Films, Nude Packing | Delivery: Ocean Shipping |

The High Quality Ce Used Clothes Baler Machine is mainly compress the used clohes, old clothings, wiper rags, wool fibers into small bales with high density, easy to transport, stock and convenient for distributor to sell to end users, it has other names such as Valvan Vertical Baling Press Front Loading Textile Fiber Single Chamber Movie,Packing Of Used Clothes baler Price,Manuanl Hydraulic Cloth Press Machine,Automatic Waste Paper Textile Press Baling Machine,Used Clothes Bale Pressing Machine For Sale / Used Clothing Baler,Compress Machine For Waste Cloth,Used Textile Press Baler,Waste Textile Compress Baler Machine,Used Clothing Press Baling Machine.

We not only have these baler machine, but have other machines such as Australia Textile Fibre Baler At Work,UT Machinery 2kg Rags Compressor,Enerpat baler 45kg Used Clothings Packing Machine,Turkey 10lb Cotton Wipers Baling Press Machine,SK BalerChina Supplier Used Clothes Baler,Oman 20lb Wipers Bagging Baler,Sri Lanka 2lb Wipers Baler,Ireland 4lb Wiping Rags Compressor Machine,Spain Low Price Waste Clothes Baler,Italy 200kg Second Hand Clothes Compactor Machine,Thailand Cheap Wiping Cloth Baling Press,CSJ baler Stand Up Waste Fabrics Baler Press Machine,Japan China Wipers Baling Press Machine,South Africa 10kg Rag Wiper Compactor,Pakistan Big Bale Textiles Baler Press Machine,Jiangsu supplier, China Wiping Cloth Bagging Machine,Huicheng China Cleaning Rags Baler,Albania Automatic packaging of wiper rag,Egypt 5kg Wiping Cloth Bagging Press,Austria 25kg Wipers Baling Press,Indonesia Cleaning Rags bagging machine,Jewel Baler Lifting Box Second Hand Clothes Compress Baler,Argentina Cotton Wiper Bales baler,Netherlands Stand Up Used Clothes Baling Machine,TCM baler Lifting Box Textiles Baler Machine,XT baler Wipping rags baler,Nantong supplier Vertical Used Clothings Baling Machine,Kuwait Low Price Old ClothesBaling Machine,Finland Cheap Wiping Cloth Baler Machine,Belgium 20lb Cotton Wipers Baler,USA 20lb Rags Baler,Slovenia Wool Bale Press 4 Doors,SK baler Fiber Press With Scale,Iran 40kg Second Hand Clothes Baler Press Machine,Bulgaria 100kg Waste Fabrics Compress Baler,France 40kg Waste Clothes Baler Press Machine,Sino baler 45kg Old Clothings Compress Baler,Croatia 2kg Cotton Wipers Baling Press,Hello baler Horizontal Cleaning Rags Baler Machine,Russia Small wiper press etc...

Please contact with us if you have any questions.

Parameter

Model | Bale Size (mm) | Bale Weight (Kg) | Power (Kw) |

VLB30 | 700X400X(300-600) | 40-90 | 5.5 |

VLB40 | 760X520X(500-900) | 80-130 | 7.5 |

VLB60 | 1100X700X(500-900) | 150-250 | 11 |

VLB80 | 1200X800X(600-1000) | 200-350 | 15 |

VLB100 | 1200X800X(600-1000) | 300-400 | 22 |

VLB120 | 1100X1100X(600-1000) | 400-600 | 30 |

VLB150 | 1350X750X(600-1200) | 500-700 | 22X2 |

If you have any special requirements, we will customize according to your special needs.

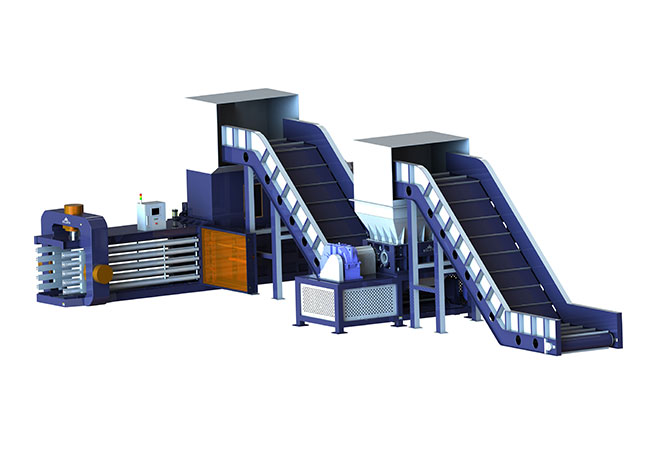

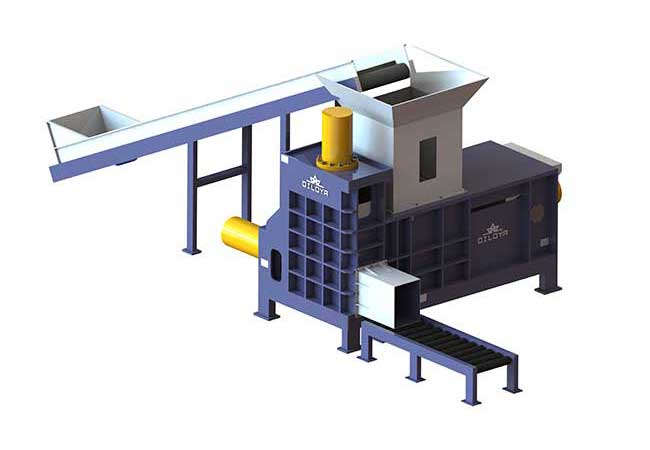

Product Show

|  |

|  |

|  |

|  |

|  |

Advantage

> Enough spare parts with lower cost to keep the machine non-stop.

> Adopts china famous pump to keep baler machine run smoothly.

> World famous brand of Siemens PLC to promise you run the machine without any worry.

> Stable hydraulic system to keep the machine run well.

> Long warranty time of the baler machine, you are no need to worry about the after-services.

> The bale weight ranges from 40kg to 1000kg, more options for your choices.

> Weight with one machine is optional, you can save cost of the machine.

Application

The baler machine can press below materials:

FAQ

> Is your price of Small Baler Machine For Used Clothes competitive?

Yes, of course, our price is competitive, our price is cheaper than other suppliers such as sinobaler, nk baler, skbaler, tcm baler, enerpat baler etc.. Because we are direct manufacturer of the baler machine, so we can promise the quality of the baler machine, and price is lower.

> Which country have you exported the Used Old Clothes Baler Machine?

We have exported the baler machine to many countries such as Japan, Thailand, Malaysia, Singapore, Indonesia, India, Pakistan, Sri Lanka, Iraq, Iran , Qatar, Kuwait, Oman, Turkey, Finland, Sweden, Norway, Iceland, Denmark, Russia, Poland, Czech, Germany, Austria, Britain, Ireland, Netherlands, Belgium, France, Greece, Romania, Bulgaria, Albania, Slovenia, Croatia, Italy, Spain, Portugal, Egypt, Chile, Argentina, Ecuador, Canada, America, USA, Australia, New Zealand, South Africa, Mexico and other countries.

> How much price of Used Cloth Baling Machine?

Price of the baler machine is different, depends on how big of the machine is, but we can give you a word that our price of the machine is lower with high quality.

> Are you a manufacturer or a trader of Fiber Press With Scale?

We are true manufacturer of used clothes baler machine, we have our own technical team, R&D team, have many processing machines, and you are warmly welcome to visit our factory personally.

> How to maintain Professional Used Clothes And Textile Compress Baler Machine?

When you were operating the baler machine, you need to clean the oil tank every 3 months, and check the wire, and oil pipe leakage or not, and also check the bolt every shift, you can find all maintenance items in the user manual.

> What are the service requirements of the Working Of Baler Machine In Textiles?

No need special requirements, just contact with our technical team, that is OK, we can get everything done.

> How can i know you are a manufacturer or trader of Bagging Press For Cotton Wipers?

You can visit our factory personally, also you can ask technical drawings such as 2D drawings 3D Drawings, we have professional technical team working on this, and will not give you these if a trader, because they don't have ability on this.

Hotline : +86 152 2134 7650

Hotline : +86 152 2134 7650 Email : info@diloya.com

Email : info@diloya.com

Product

Product Phone: +86 152 2134 7650

Phone: +86 152 2134 7650 E-mail: info@diloya.com

E-mail: info@diloya.com Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China

Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China