A hydraulic press compresses metal scraps (like iron, aluminum, copper, etc.) into dense bales or bl...

| Basic Infomation | |

Status Of Machine: Totally New; | Motor: China Famous Brand; |

| Additional Information | |

Lead Time: 15 Days; | Brand: Diloya; |

| Package And Delivery | |

Package: Wood package, Plastic Films, Nude Packing | Delivery: Ocean Shipping |

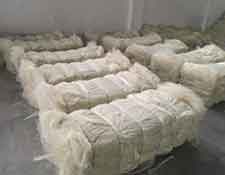

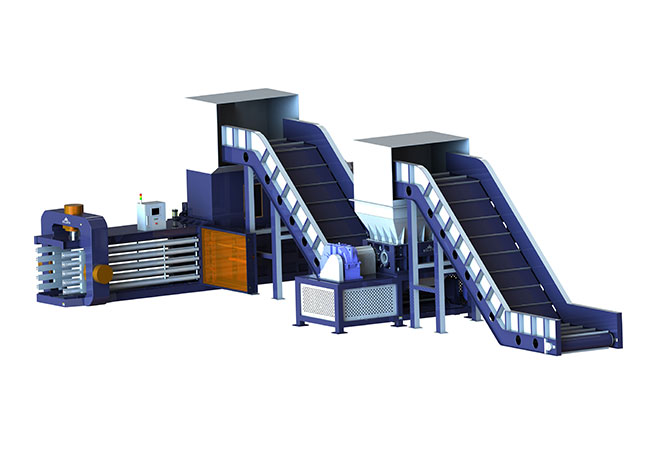

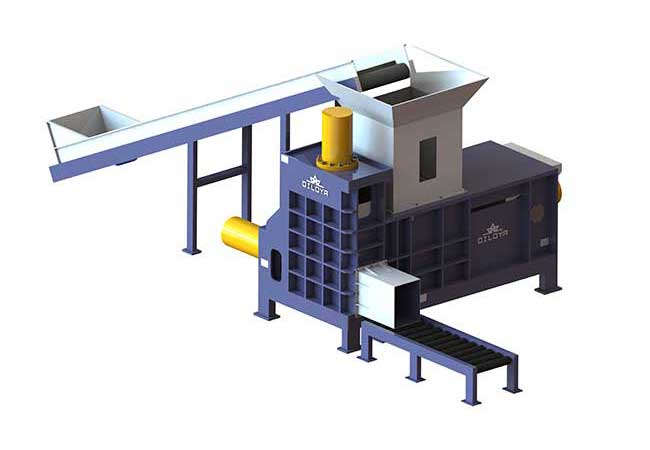

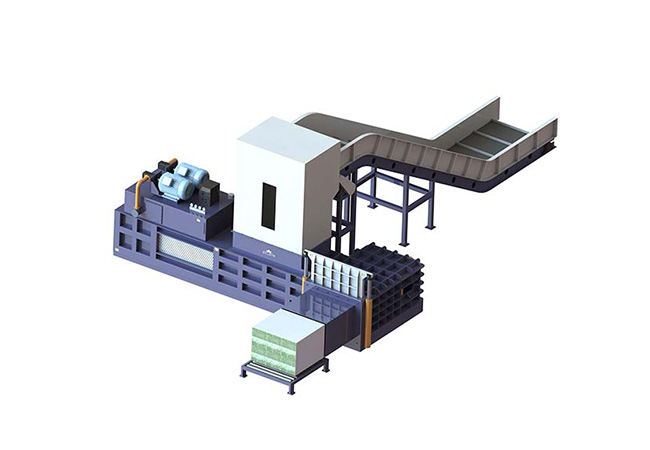

The Raw Jute Bailing System In Bangladesh is mainly compress the sisal fiber, coir fiber, and other natural fibers into small bales with high density, easy to transport, stock and save labor cost, make more money, it has other names such as Coconut Compress Fiber Baling Machine,Sisal Baling Machine 200Kg,Bale Press Short Fiber,Coir Fiber Baling Machine,Bales Of Jute Fibre,High Quality Square Sisal Baler Twine,Raw Jute Bale Press Price,Coconut Fiber Baler Machine,Baler For Palm Fiber.

We not only have these baler machine, but have other machines such as Netherlands Hydraulic Alfalfa Grass Baler Machine, Jiangsu supplier, High Density Sisal Fiber Baler, Pakistan Automatic Paper Scrap Baling Machine, CSJ baler High Density Corn Core Baler Machine, Ireland Close End Occ Packing Machine, Iran How To Select The Proper Cardboard Baler, Argentina Durable Paper Tube Shredder Crusher, Oman Vertical Aluminum borings block making machine, Italy Automatic briquetting machine for Steel swarfs, CSJ baler High density Brass Borings briquetting press, Thailand Stable Paper Reels Shredder Crusher, Canada Fast Waste Cans Press Baler, Poland 50kg Scrap Clothes Packing Machine, Huicheng Economical Pet Bottles Compactor, Hello baler Close End Cardboard Box Compress Baler, Chile Ubc Recycling Baler, Australia High Density Hydraulic briquetting machine for brass swarfs, Croatia China Marine Use Compress Baler, New Zealand Three Rams Wooden Shavings Packer Machine, TCM baler Hydraulic Coir Fiber Baler Machine, Britain Steel chips briquetting press, XT baler Durable PE Barrels Dual Shaft Shredder, Japan Industrial Cardboard Compactor, Sri Lanka Durable PP lumps Single Shaft Shredder, Indonesia Occ Baling Machine In India, India Conveyor Belt Waste Bottles Press Machine, Bulgaria Small Copper Scrap Crocodile Shear, Belgium Vertical Scrap Carton Baling Machine, SK Baler10kg Wiping Rags Compressor Machine, Denmark Turn Out Used Metal Baling Press, SK baler Automatic Cardboard 1 Ton Press Machine, Turkey Jmc Metal Baler machine, Sweden China Supplier Sisal Compactor Machine, USA China Metal Millings briquetting press, Malaysia Automatic Corncob granules Compressor, Romania Aluminum Cans Crushed By Compactor, Greece Vertical briquette machine for Aluminum borings, Russia 5kg Cleaning Rags Baler Machine, Enerpat baler Big Used Metal Compactor, Iraq High Efficiency Paper Box Compressor Machine etc...

Please contact with us if you have any questions.

Parameter

Model | VDD100 | VDD150 | VDD200 | VDD250 |

Bale Size | 1530x360x(400-800)mm | 1350x550x(400-800)mm | 1370x530x(300-600)mm | 1450x550x(300-600)mm |

Bale Weight | 100-200kg | 120-250kg | 100-200kg | 100-200kg |

Motor Power | 18.5kw | 22 | 30 | 37 |

Machine Weight | 3560kg | 4210kg | 5460kg | 6120kg |

If you have any special requirements, we will customize according to your special needs.

Product Show

|  |

|  |

|  |

|  |

|  |

Advantage

> Output capacity can be up to 6-10 bales per hour, more efficient.

> Schneider electrical components prolong the service life of the machine.

> 24 hours reply, video, phone call, email support, if any question, we response at first time.

> Strong structure of the machine, reliable, stable and durable, let you make more money.

> Stable hydraulic system to keep the machine run well.

> Weight with one machine is optional, you can save cost of the machine.

> Install the foot wheels, can be easily move to any place you want, very convenient.

Application

The baler machine can press below materials:

FAQ

> How to maintain Bailing Of Coir Fiber China?

When you were operating the baler machine, you need to clean the oil tank every 3 months, and check the wire, and oil pipe leakage or not, and also check the bolt every shift, you can find all maintenance items in the user manual.

> Is your price of Latest 100 Kg Hydrlic Fiber Balling Machine competitive?

Yes, of course, our price is competitive, our price is cheaper than other suppliers such as sinobaler, nk baler, skbaler, tcm baler, enerpat baler etc.. Because we are direct manufacturer of the baler machine, so we can promise the quality of the baler machine, and price is lower.

> Do you have a agent of Fibre Pressing Machines in our country?

No, we don't have agent or representative in your country, we directly export the machine to our end users, this way, the price will be lower, and end users can get more money.

> What is package of Vertical Hydraulic Palm Fiber Baler?

Generally speaking, there are two packages of the machine, wooden package, and plastic films, wooden package is mainly for small machine with LCL shipment, and plastic films mainly for big machine with FCL shipment.

> How do I decide the model of Jute Balling Press Machine Price that I need?

First, you need to know what bale size and bale weight are popular in your local market, then you produce the bale weight and bale size, and we can suggest you suitable model of wiper baler machine accordingly, Before this, you need to make investigation in your market, you can inquire your end user etc..

> How can we install the Baling Press Machine For Jute?

The baler machine is not disassembled when shipping, so you just put it on the horizontal ground, adding hydraulic oil, connect to the power supply, then test and operate the machine per user manual, that is OK, if you have any questions, you can contact with us any time.

> What profits can we get from the Coir Fibre Double Chamber Hydraulic Baling Machine?

You need to know price of recycling the sisal fiber baler machine, and price of the bales you sell to your end users or distributors, then you can know how much profits you will get by this machine.

Hotline : +86 152 2134 7650

Hotline : +86 152 2134 7650 Email : info@diloya.com

Email : info@diloya.com

Product

Product Phone: +86 152 2134 7650

Phone: +86 152 2134 7650 E-mail: info@diloya.com

E-mail: info@diloya.com Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China

Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China