What is price of China Supplier Used Beverage Cans Compress Baler? How to maintain High Speed Alumin...

| Basic Infomation | |

Motor: China Famous Brand | Warranty Time: 1 Year |

| Additional Information | |

PLC Brand: Siemens | Packaging: Nude Packing |

| Package And Delivery | |

Package: Wood package, Plastic Films, Nude Packing | Delivery: Ocean Shipping |

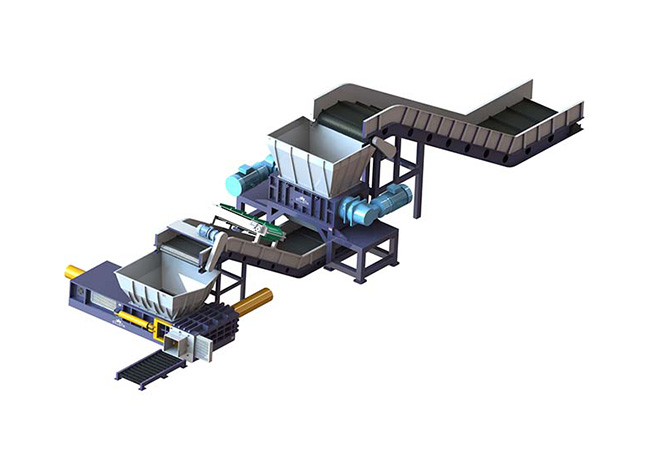

CMS series shearing baler press machine mainly compress scrap metal with low weight and big volume, such as waste cans tins, stainless steel scrap, copper scrap, light metal scrap, waste aluminum profiles, aluminum chips, non-ferrous metal scrap etc...

A Waste Metal Scrap Shear Baling Machine is a specialized piece of equipment used in the recycling industry to process and prepare metal scrap for recycling. This machine combines the functions of both shearing and baling to efficiently handle and compact different types of metal scrap. The primary goal is to cut and compress metal scrap into manageable and standardized bales for ease of storage, transportation, and recycling.

Here's a general overview of how a Waste Metal Scrap Shear Baling Machine typically works:

1. Shearing Mechanism:

The machine is equipped with a shearing mechanism, often in the form of a large blade or blades, that is used to cut and size the metal scrap. The shearing process reduces the scrap into smaller, more manageable pieces.

2. Feeding System:

Metal scrap is fed into the machine, either manually or through a conveyor system, to be processed by the shearing mechanism.

3. Compression Chamber:

The sheared metal pieces are then fed into a compression chamber where a hydraulic ram or press applies pressure to compact the scrap into dense bales.

4. Hydraulic System:

Similar to other hydraulic machines, the Waste Metal Scrap Shear Baling Machine utilizes a hydraulic system to generate the force needed for both shearing and baling. A hydraulic pump, hydraulic fluid, and hydraulic cylinders work together to power the machine.

5. Baling Process:

As the hydraulic ram exerts force, the sheared metal pieces are compressed into tightly packed bales.

6. Bale Discharge:

Once the compression process is complete, the bale is often pushed out to maintain its shape during handling and transportation.

7. Bale Ejection:

The finished bale is then ejected from the machine and can be stacked or transported for further processing or recycling.

This type of machine is particularly useful for processing a variety of metal scraps, including steel, aluminum, copper, and other non-ferrous metals. The combination of shearing and baling in a single machine enhances efficiency and reduces the need for separate processing steps.

Waste Metal Scrap Shear Baling Machines are crucial in metal recycling operations, helping to streamline the handling and processing of metal scrap and promoting resource conservation through recycling. They are often employed in scrapyards, metal processing facilities, and recycling centers.

Video

Parameter

Model | CMS100 | CMS125 | CMS160 | CMS200 | CMS250 | CMS315 |

Chamber Size(mm) | 1200x700x400 | 1400x700x300 | 1500x1000x400 | 1600x1200x450 | 1800x1300x500 | 2000x1400x500 |

Bale Size(mm) | 400x250mm | 300x300mm | 400x400mm | 450x450mm | 500x500mm | 500x500mm |

Bale Weight(Kg) | 20-40kg | 40-70kg | 70-150kg | 120-180kg | 150-250kg | 200-300kg |

Power(Kw) | 22kw | 30kw | 37kw | 2x30kw | 2x37kw | 2x45kw |

Machine Weight(Kg) | 5680kg | 7850kg | 9820kg | 15360kg | 18720kg | 22580kg |

If you have any special requirements, we will customize according to your special needs.

Product Show

|  |  |  |

|  |  |  |

|  |  |  |

|  |  |  |

Advantage

> Adopts simple structure, easy to operate and maintain.

> Adopts Two rams structure to keep high bale density.

> Can press varous of metal scraps, non metal scraps, stainless steel scrap, metal chips etc...

> Output capacity can be up to 30-60bales per hour, more efficient.

> Lifelong after services let you have no any concern, get more porfits.

> Schneider electrical components prolong the service life of the machine.

> World famous brand of Siemens PLC to promise you run the machine without any worry.

> One Button automatic PLC Control, just need to push one button, you can operate the machine continuously.

> Enough spare parts with lower cost to keep the machine non-stop.

> Remote Control is optional, can archive automatic operation without worker.

> 24 hours reply, video, phone call, email support, if any question, we response at first time.

> Strong structure of the machine, reliable, stable and durable, let you make more money.

> Latest design of the machine to let you use the best the machine all the time.

Application

The baler machine can press below materials:

FAQ

> Do you have a customer case of How To Bale Aluminum Cans in our country for our reference?

We have many customers over the world, and one issue that we all signed the secret agreement with our customers, and then are not wiling to let other customers to visit their machines, as we all know, Peers are enemies.

> Is your price of Cans Baling System Plant competitive?

Yes, of course, our price is competitive, our price is cheaper than other suppliers such as tf baler, eco baler, wanshida baler, tcm baler, enerpat baler etc.. Because we are direct manufacturer of the baler machine, so we can promise the quality of the baler machine, and price is lower.

> What is trade term of Aluminium Tin Press Machine?

Trade term of the baler machine are FOB, CIF, CNF, these 3 terms, and we also can per your requirements.

> What is cooling system of Hydraulic Baler For Steel Cans?

Normally speaking, we have types of cooling system, one is water cooling, this cooling system is economical and easy to achive cooling effect, and another type is industrial chiller

> How to install Aluminum Cans Crushed By Compactor?

For small baler machine, we will not disassemble it when shipping, you just need to add hydraulic oil and connect to the electrical power, then operate per user manual, that is Ok, for bigger one, we will make detail marks when disassembling the machine, you just only need to assemble the machine per marks, that is alright; and you can contact with our technical team when you have any problems.

> How do I decide the model of Auto Aluminum Can Press Machine that I need?

First, you need to know what bale size and bale weight are popular in your local market, then you produce the bale weight and bale size, and we can suggest you suitable model of wiper baler machine accordingly, Before this, you need to make investigation in your market, you can inquire your end user etc..

> What are the service requirements of the Oil Tin Press Machine?

No need special requirements, just contact with our technical team, that is ok, we can get everything done.

> Are you a manufacturer or a trader of Empty Tin Cans Compressing And Baling Machine?

We are true manufacturer of scrap metal baler machine, we have our own technical team, R&D team, have many processing machines, and you are warmly welcome to visit our factory personally.

Hotline : +86 152 2134 7650

Hotline : +86 152 2134 7650 Email : info@diloya.com

Email : info@diloya.com

Product

Product Phone: +86 152 2134 7650

Phone: +86 152 2134 7650 E-mail: info@diloya.com

E-mail: info@diloya.com Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China

Address: No. 888, West Two HuanHu Road, Shanghai Free Trade Zone, China